RainguardPro

Clear-Seal™ 100% Urethane Heavy Duty Coating

Clear-Seal™ 100% Urethane Heavy Duty Coating

Couldn't load pickup availability

Clear-Seal 100% is a single-part urethane coating that creates a protective film for painted and unpainted surfaces. This product creates a hard glossy film that is more UV resistant, stain resistant, and hot tire resistant than that of Clear-Seal acrylic urethane. It also protects against physical abrasion and spills. For a faster cure time use Clear-Seal 100% Urethane Two-Part Kit, which also increases physical and chemical resistance.

Details

Details

What It Is: A glossy finish coat for decorative surfaces or surfaces subject to foot traffic

Surface Types: Concrete, Wood, Brick, Masonry Block (see TDS for full list)

Formulation: A Water-based Acrylic Urethane

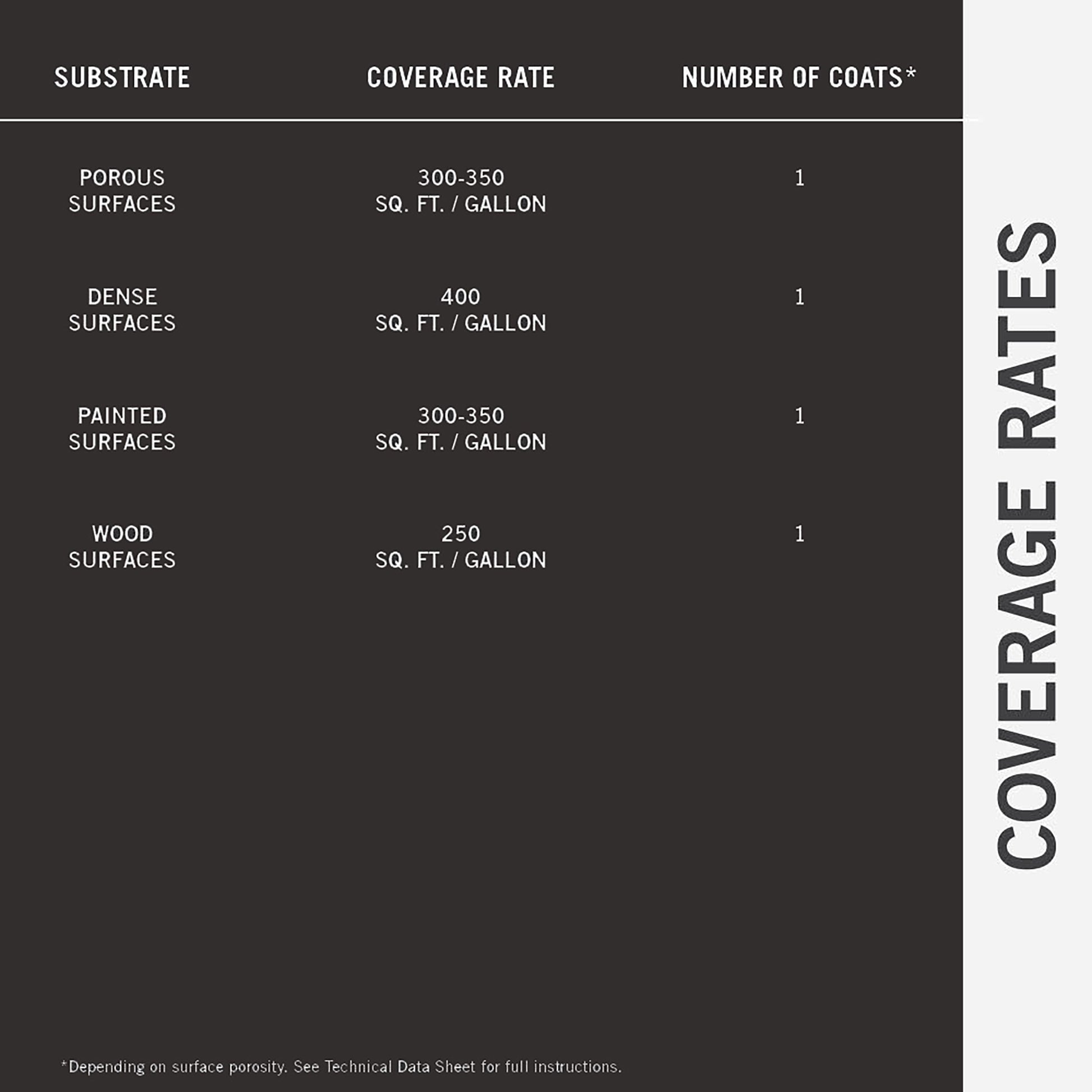

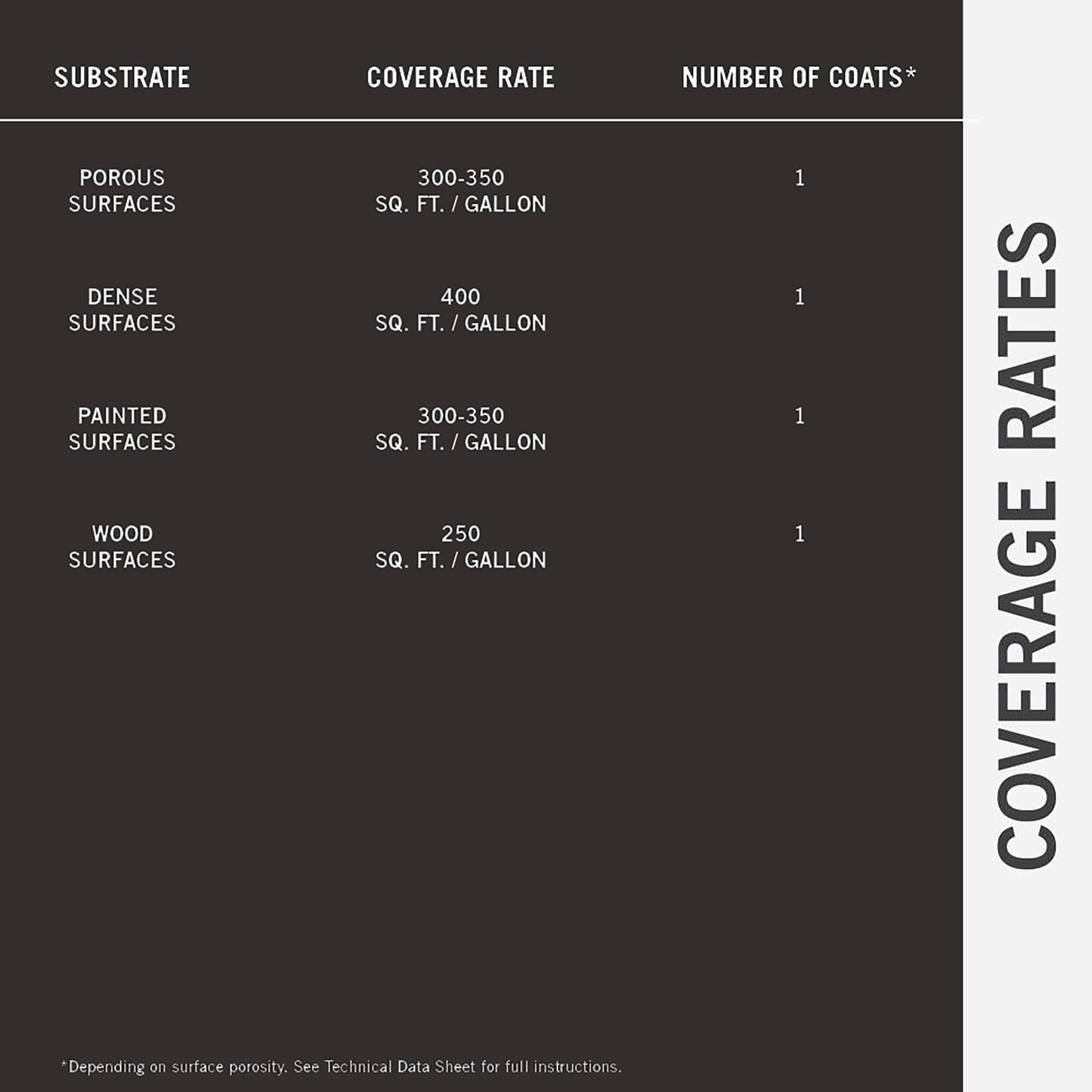

Coverage Rate: Approx. 200-400 sq. ft. / gallon (See TDS for details)

Share

More Details

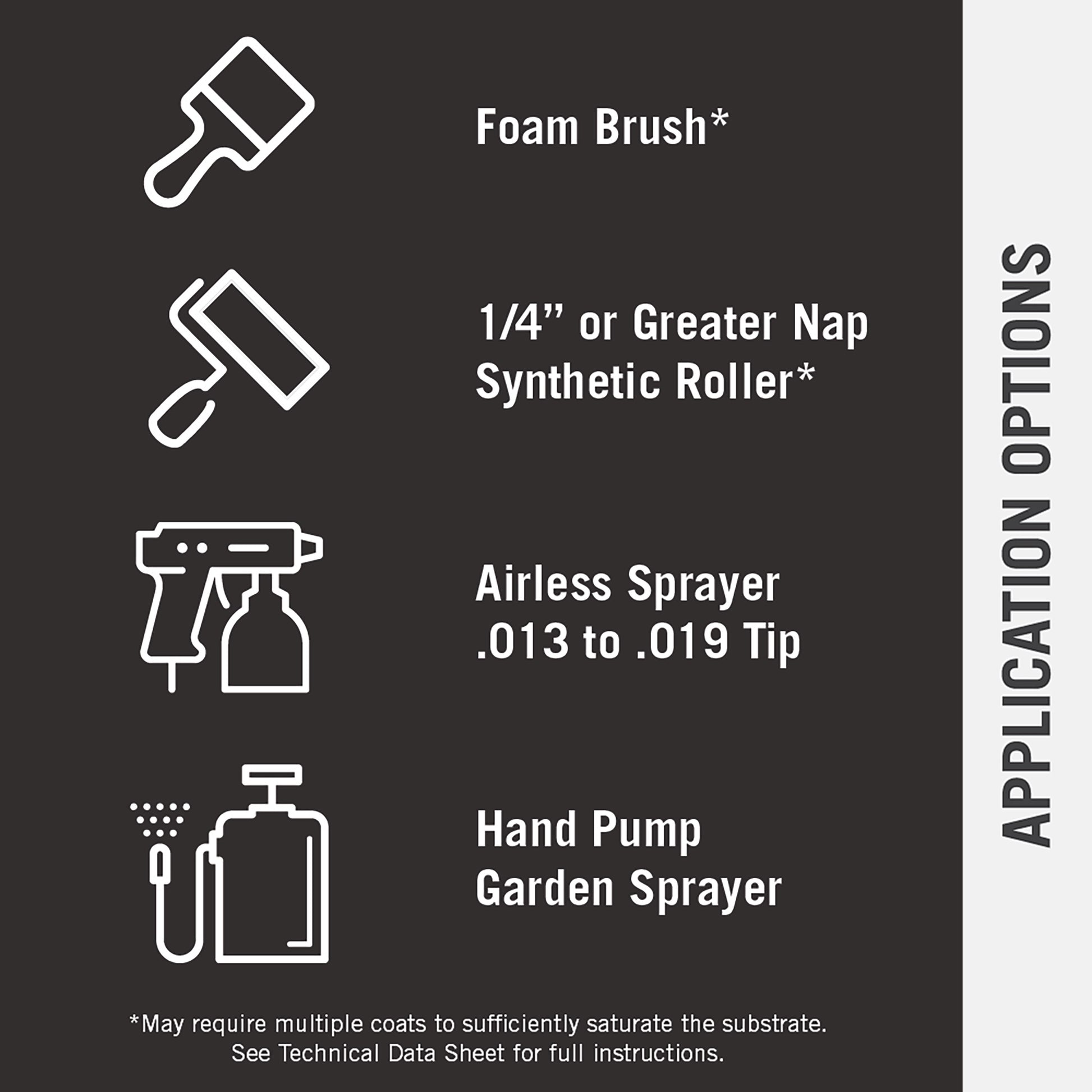

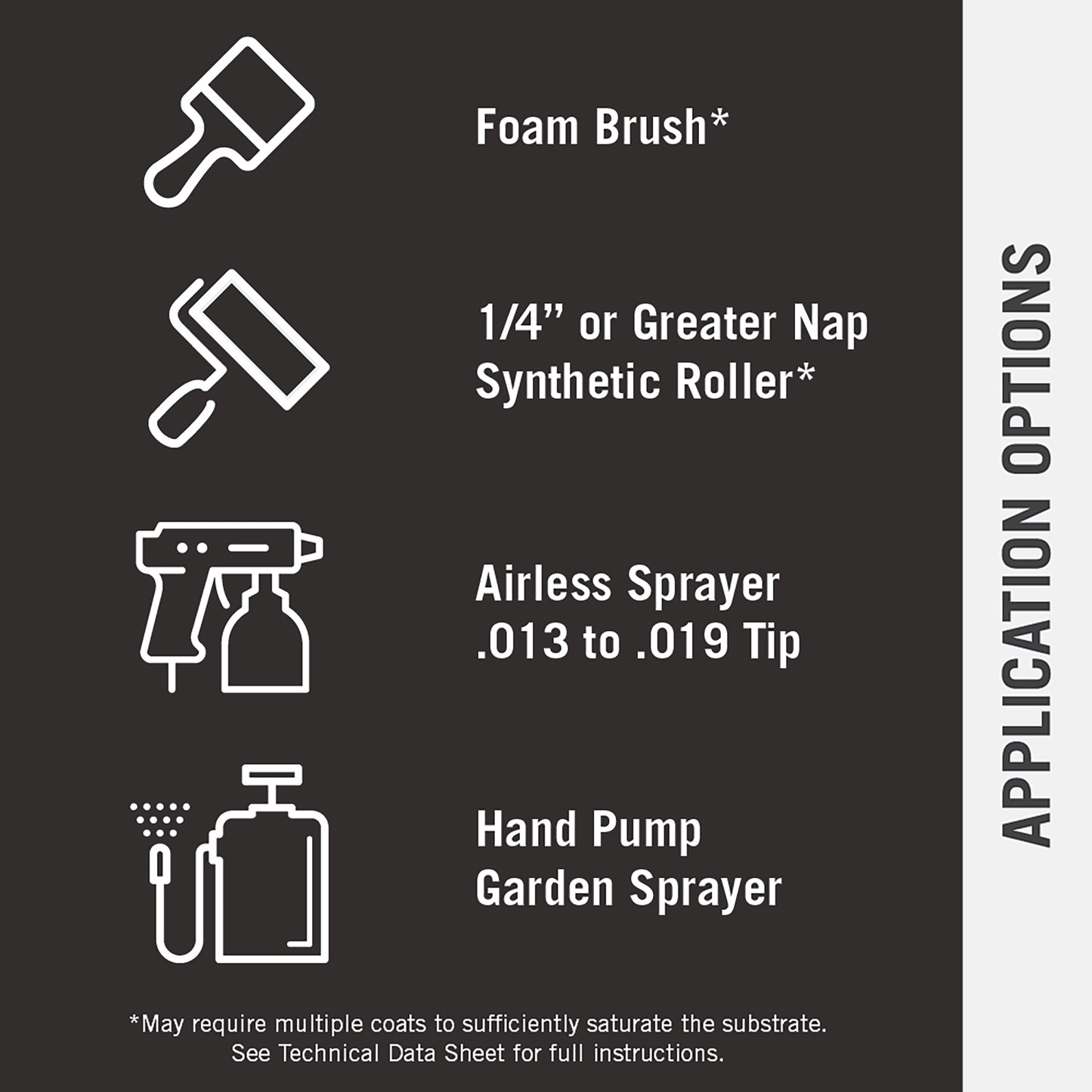

How To Apply

Brush, roll, or spray to apply Clear-Seal.

Impact And Wear Resistant

Tough and durable protection against foot traffic. Resists acids, bases, gasoline, alcohol & oil.

Superior Quality Coating

Will never yellow, crack, or peel over time, even in direct sunlight.

Safe For The Applicator, End-User, and Environment

Contains 50 g/L V.O.C.’s, no carcinogens, very low odor and can be applied on interior and exterior surfaces.