RainguardPro

Micro-Seal® Silane / Siloxane Water Repellent

Micro-Seal® Silane / Siloxane Water Repellent

Couldn't load pickup availability

Micro-Seal Silane/Siloxane Water Repellent a clear penetrating water repellent that is non-yellowing, low odor, zero VOC, and non-toxic. Formulated to not be affected by weathering, salt, dirt, freezing temperatures, UV light, and wind-driven rain, among many other damaging elements. Micro-Seal dries down to a clear, natural finish that does not change the surface texture or color. Micro-Seal is eligible for a material warranty of up to 10 years.

Details

Details

What It Is: A water repellent that provides invisible moisture protection

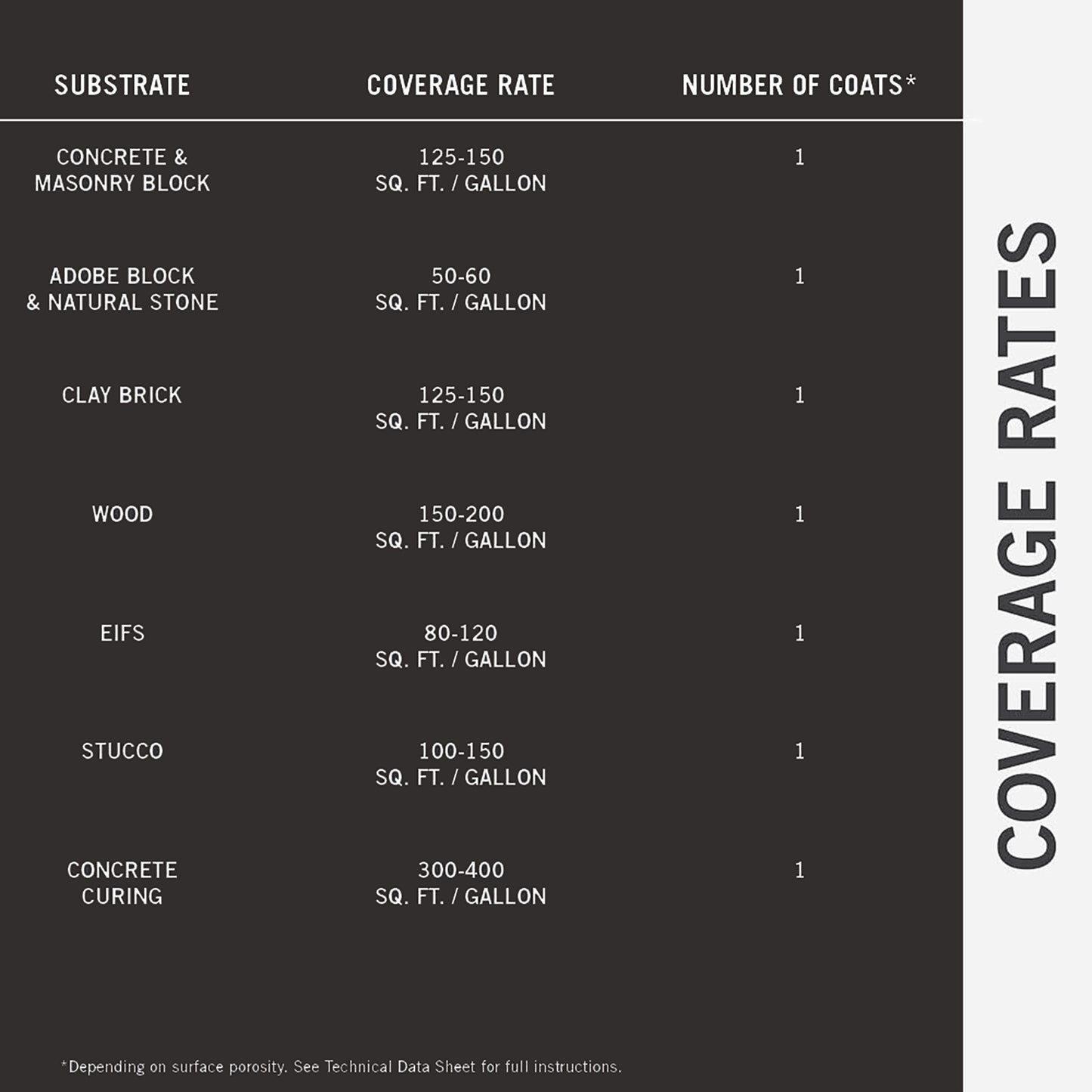

Surface Types: Concrete, Wood, Masonry, Paver (see TDS for full list)

Formulation: A Silane/Siloxane Blend

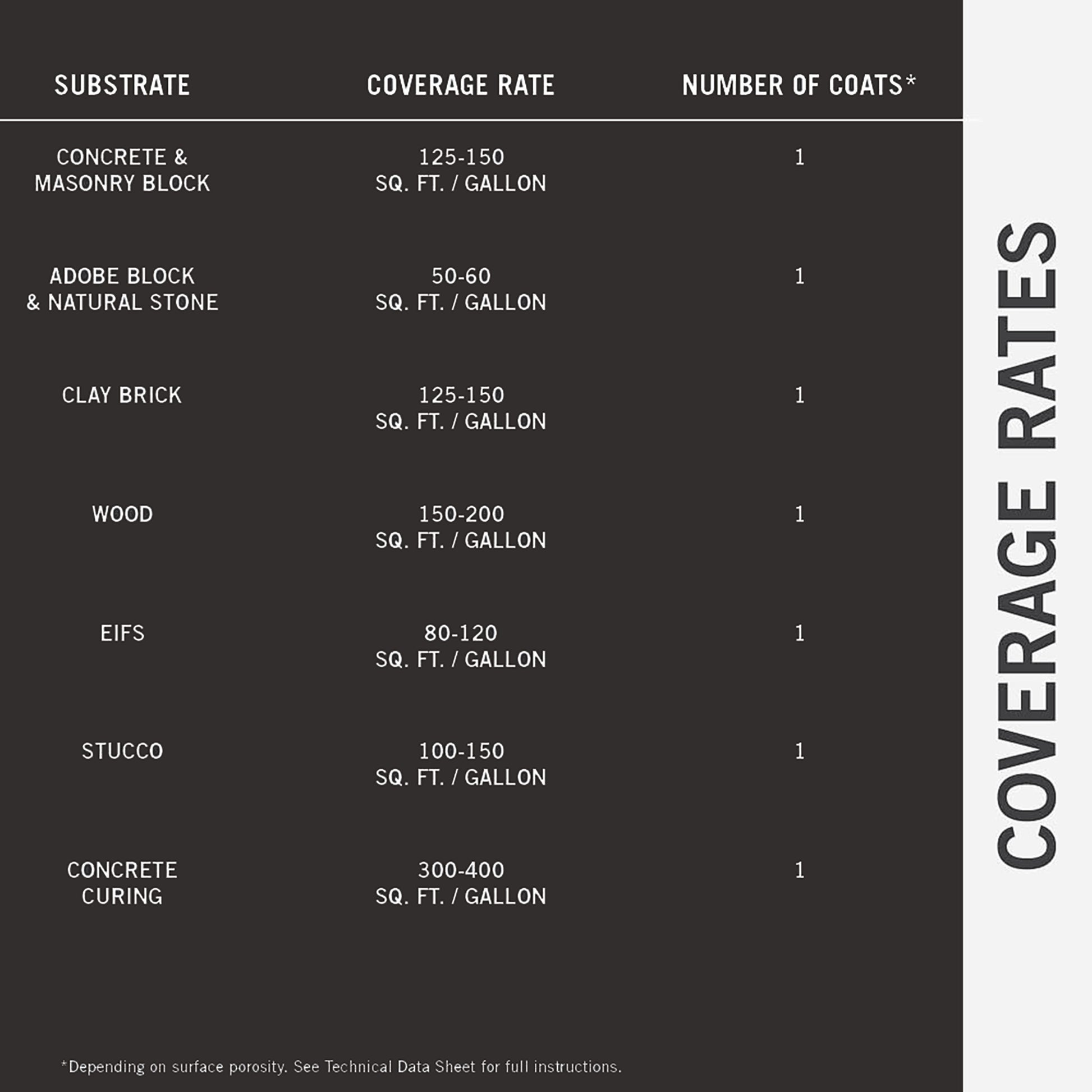

Coverage Rate: Approx. 40-400 sq. ft. / gallon (See TDS for details)

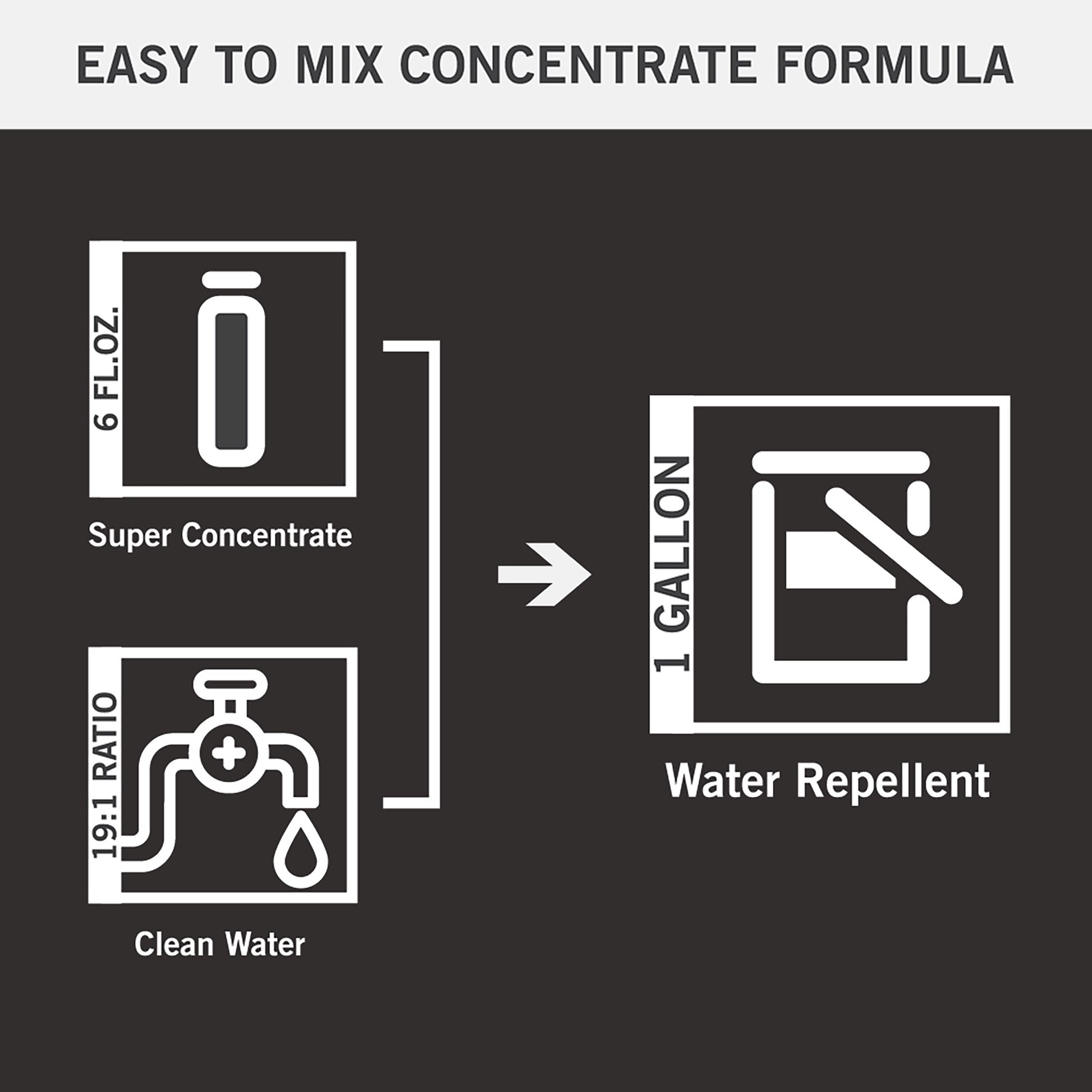

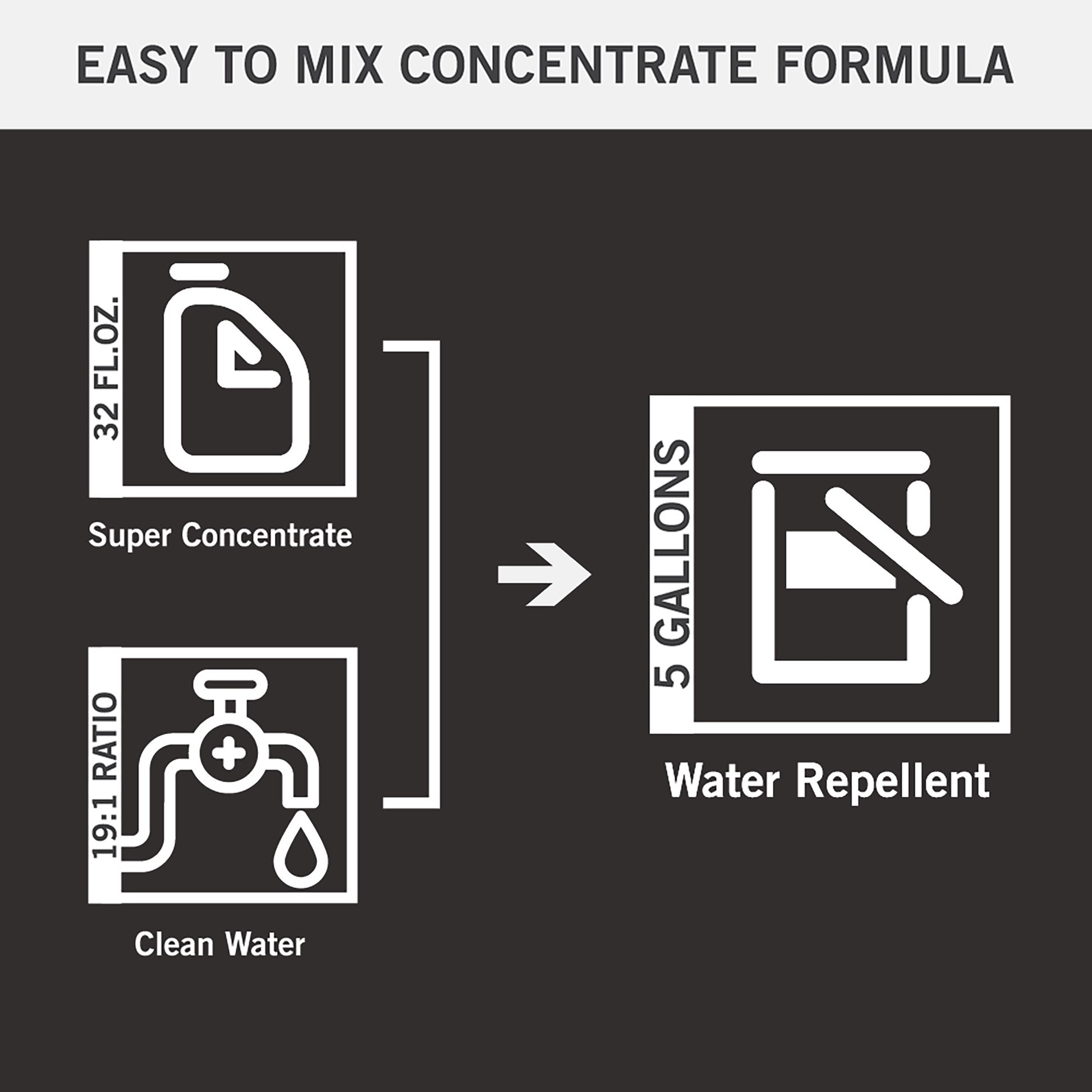

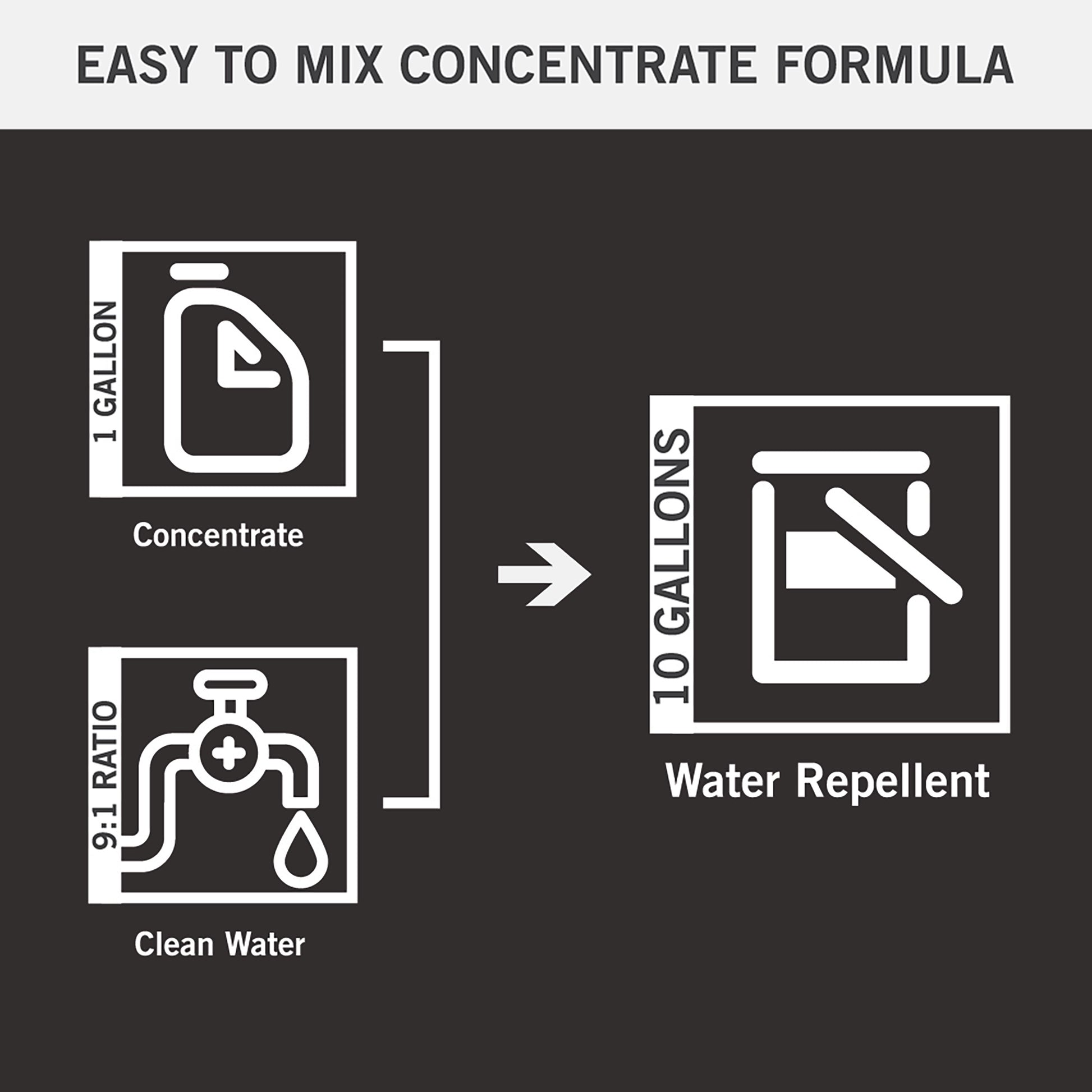

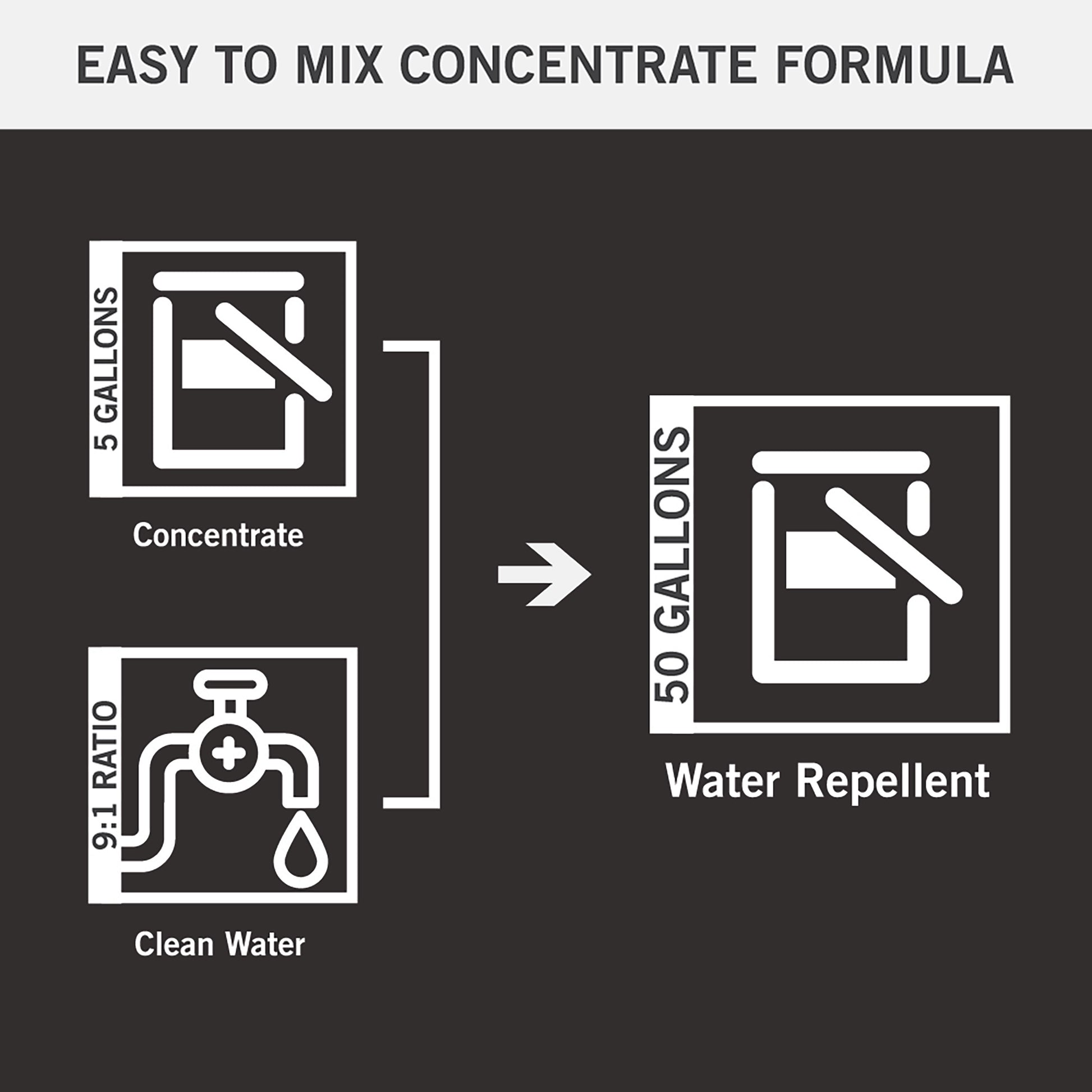

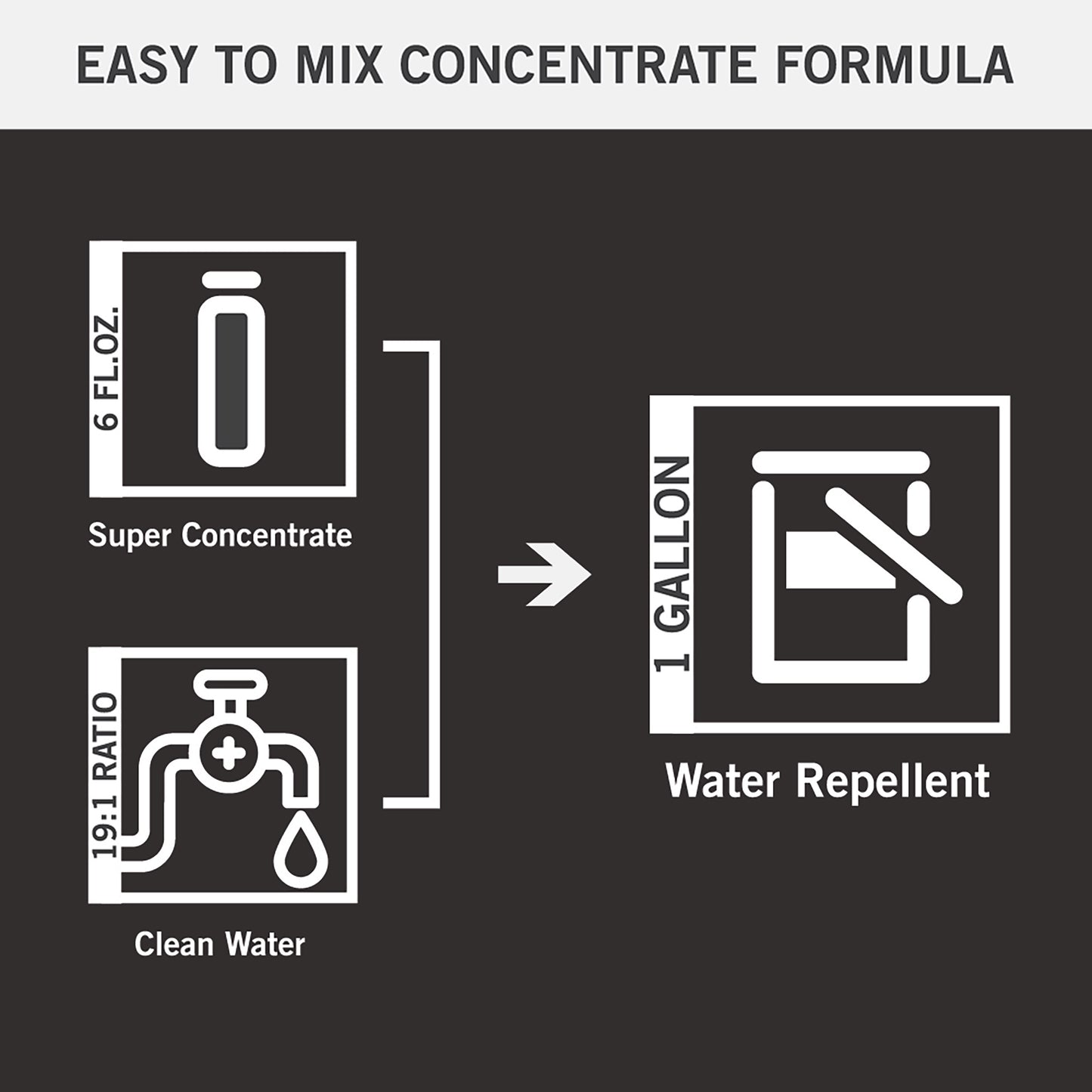

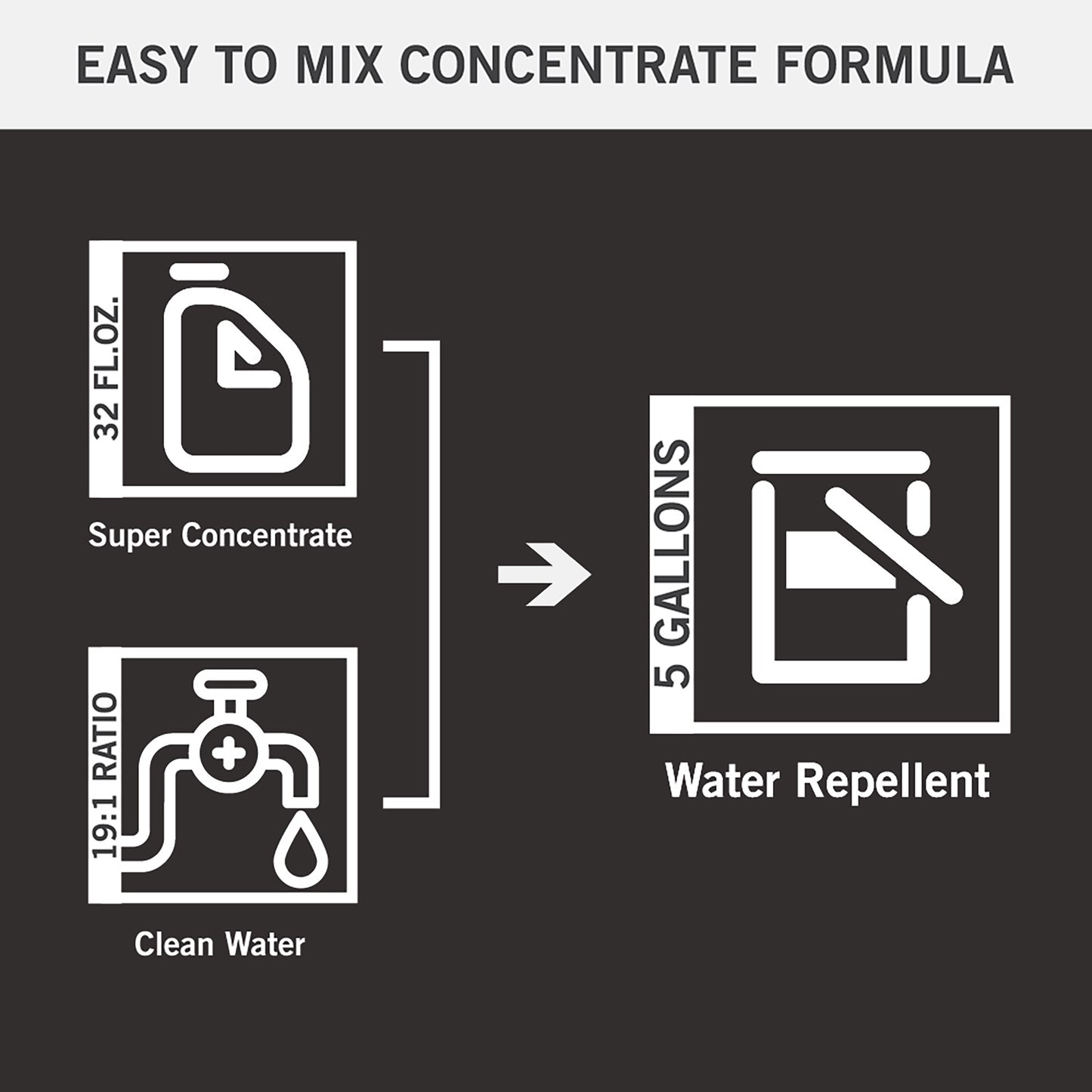

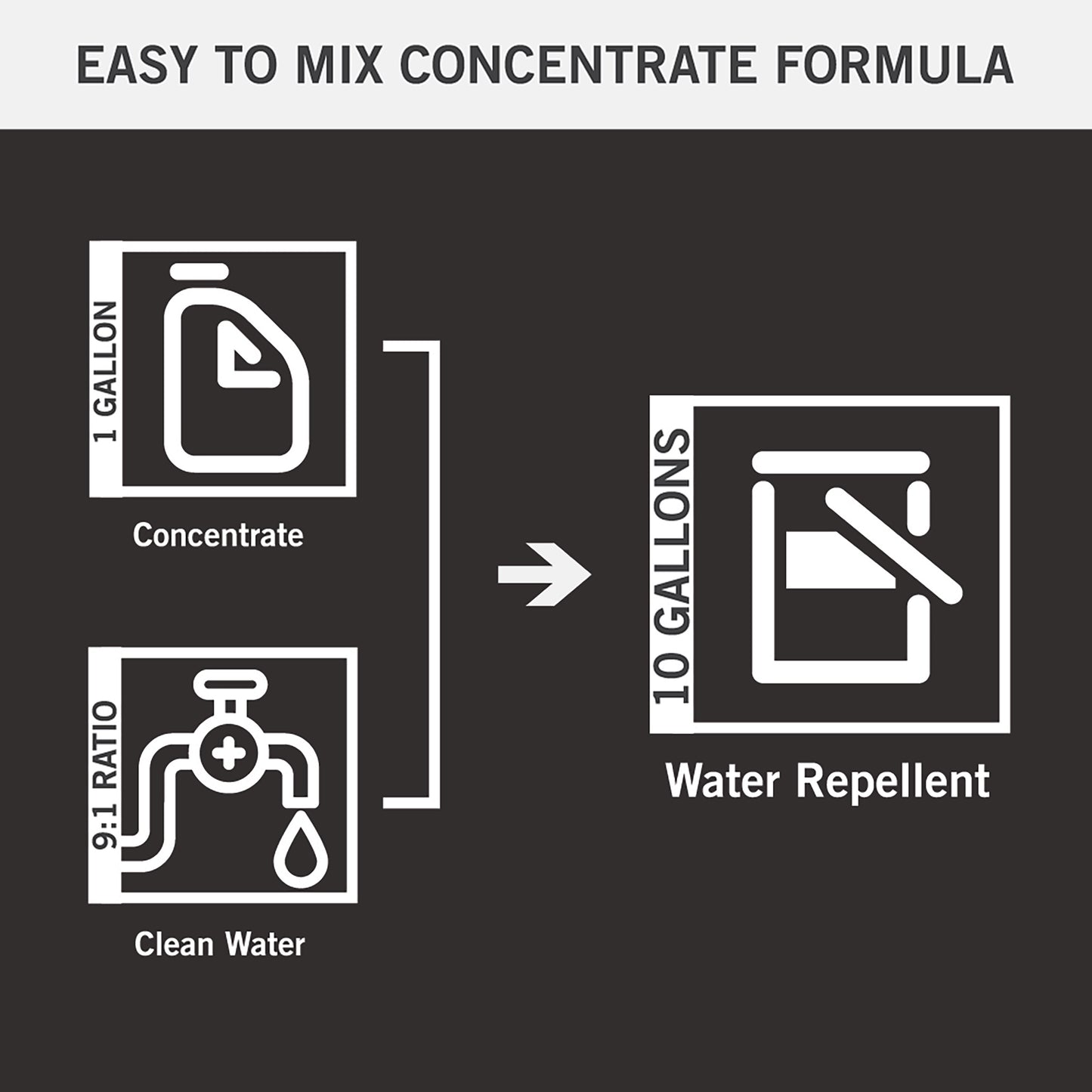

Why Choose A Concentrate?

Why Choose A Concentrate?

The Benefits of Using and Specifying Concentrates:

- Reduces carbon footprint

- Reduces job site and landfill waste

- Reduces worker and supply chain fatigue

Share

More Details

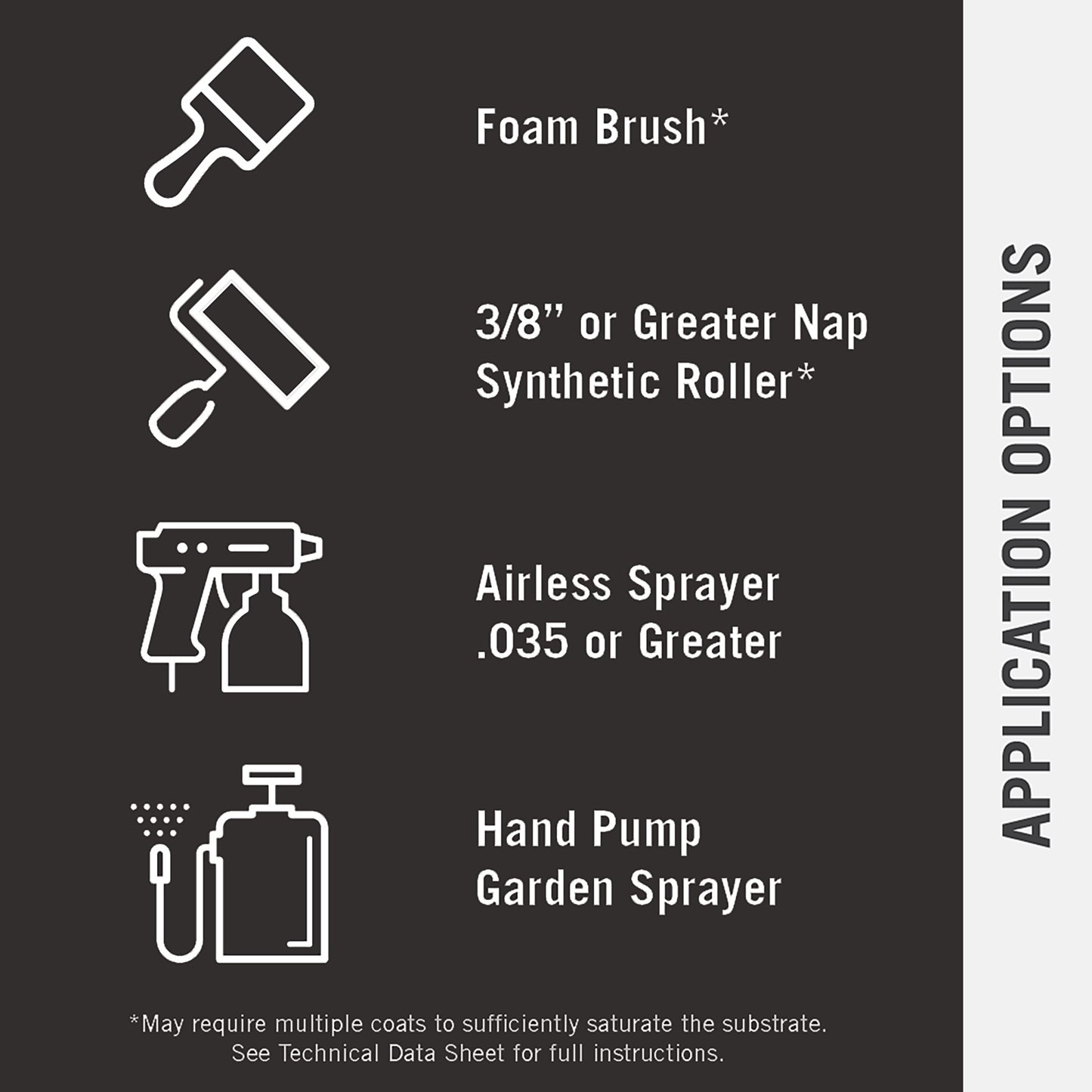

How To Apply

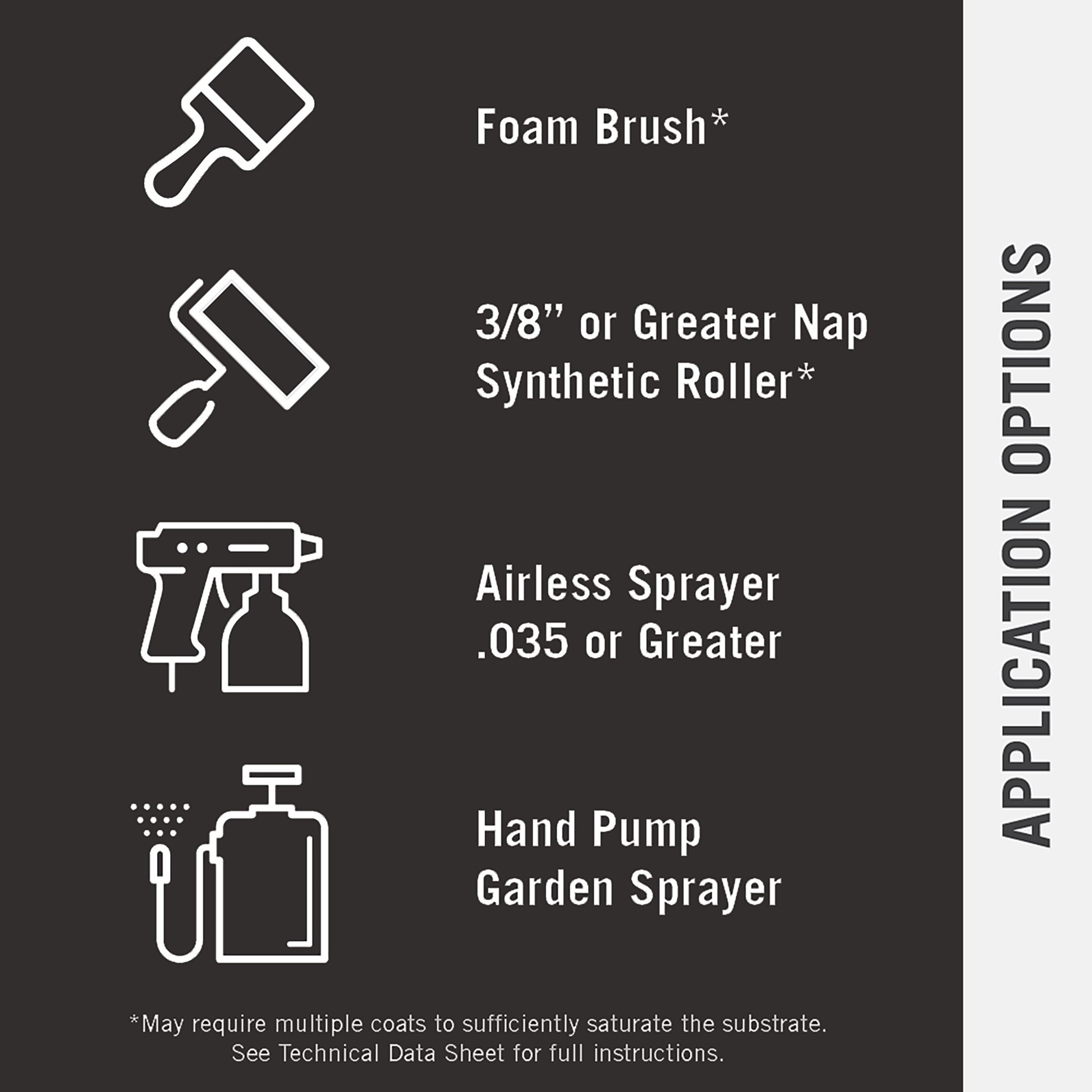

Spray on easily in a flood coat using an airless sprayer.

What is Micro-Lok®?

A proprietary ingredient that creates a micro-molecular chemical and mechanical bond between the water repellent chemicals and the substrate.

Preserve The Natural Look of the Project

Dries With A Natural Finish

Micro-Seal provides a non-yellowing, 100% breathable, and invisible water repellent protection that will not change surface look or texture.

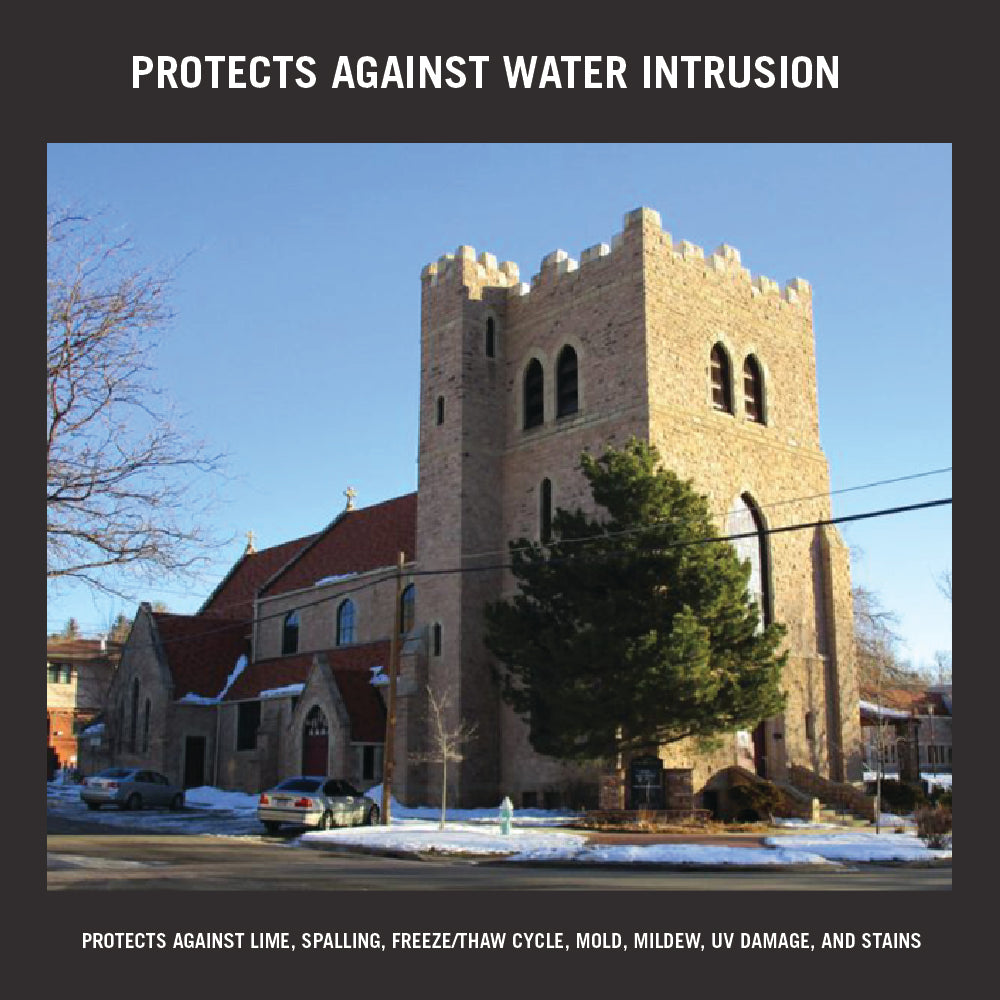

Protect Surfaces from Damage Caused by Moisture

Protect your project from water intrusion, preventing efflorescence, lime, spalling, freeze/thaw damage, stains, mold, and mildew.

Safe For The Applicator, End-User, and Environment

Contains 0 g/L V.O.C.’s, no carcinogens, very low odor and can be applied on interior and exterior surfaces.