RainguardPro

Plugger™ 25 Porous Surface Acrylic Sealer

Plugger™ 25 Porous Surface Acrylic Sealer

Couldn't load pickup availability

Plugger 25 is an acrylic-based semi-satin sealer with a clear finish. Plugger 25 acrylic sealer protects porous and painted wood and masonry surfaces from moisture damage and can be used as a primer to bind chalky surfaces. Plugger 25 is eligible for a material warranty of up to 5 years.

Details

Details

What It Is: An acrylic sealer with 25% solids for priming and binding chalky surfaces

Surface Types: Concrete, Brick, Stone, Stucco (see TDS for full list)

Formulation: A Water-based Silicone Acrylic Blend

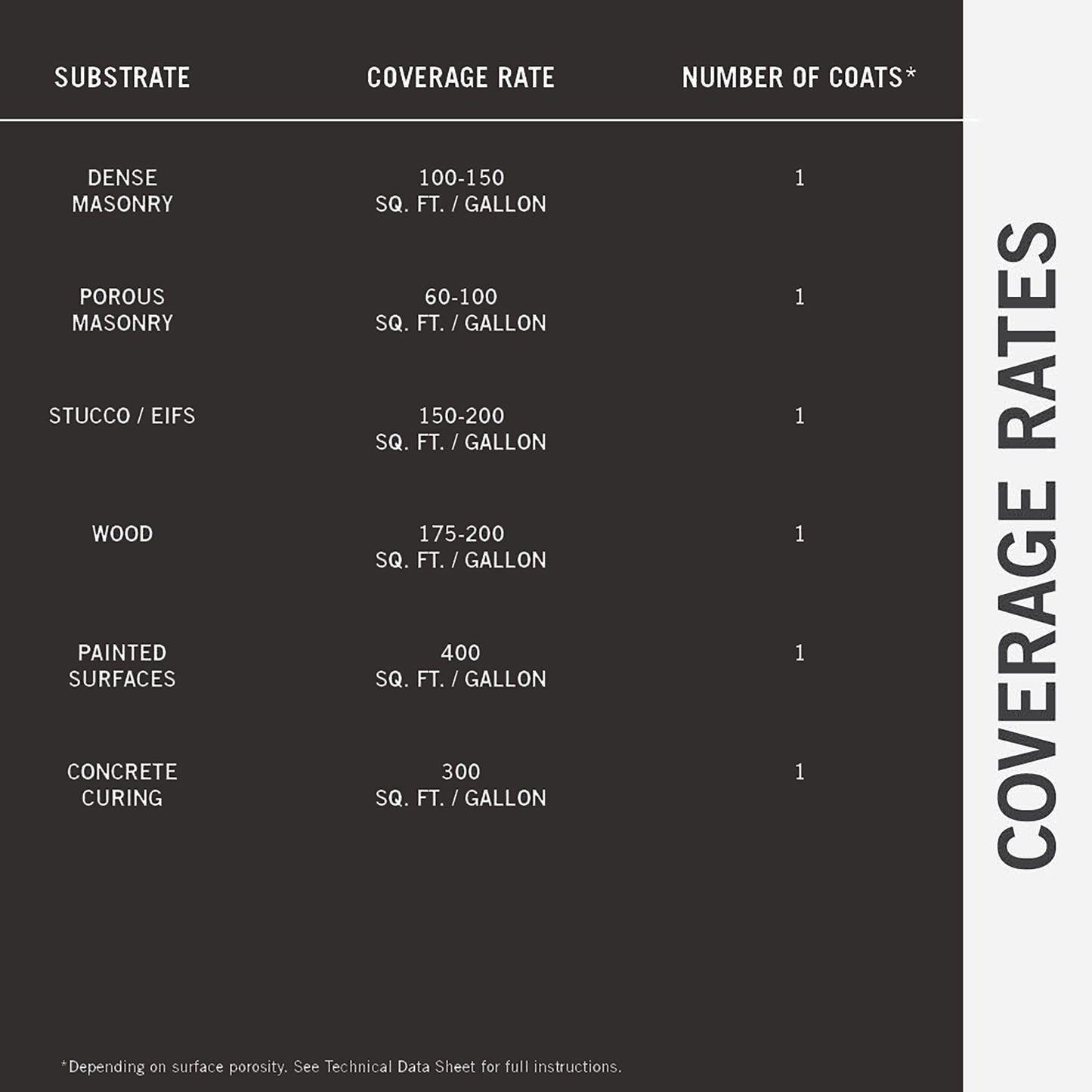

Coverage Rate: Approx. 60-400 sq. ft. / gallon (See TDS for details)

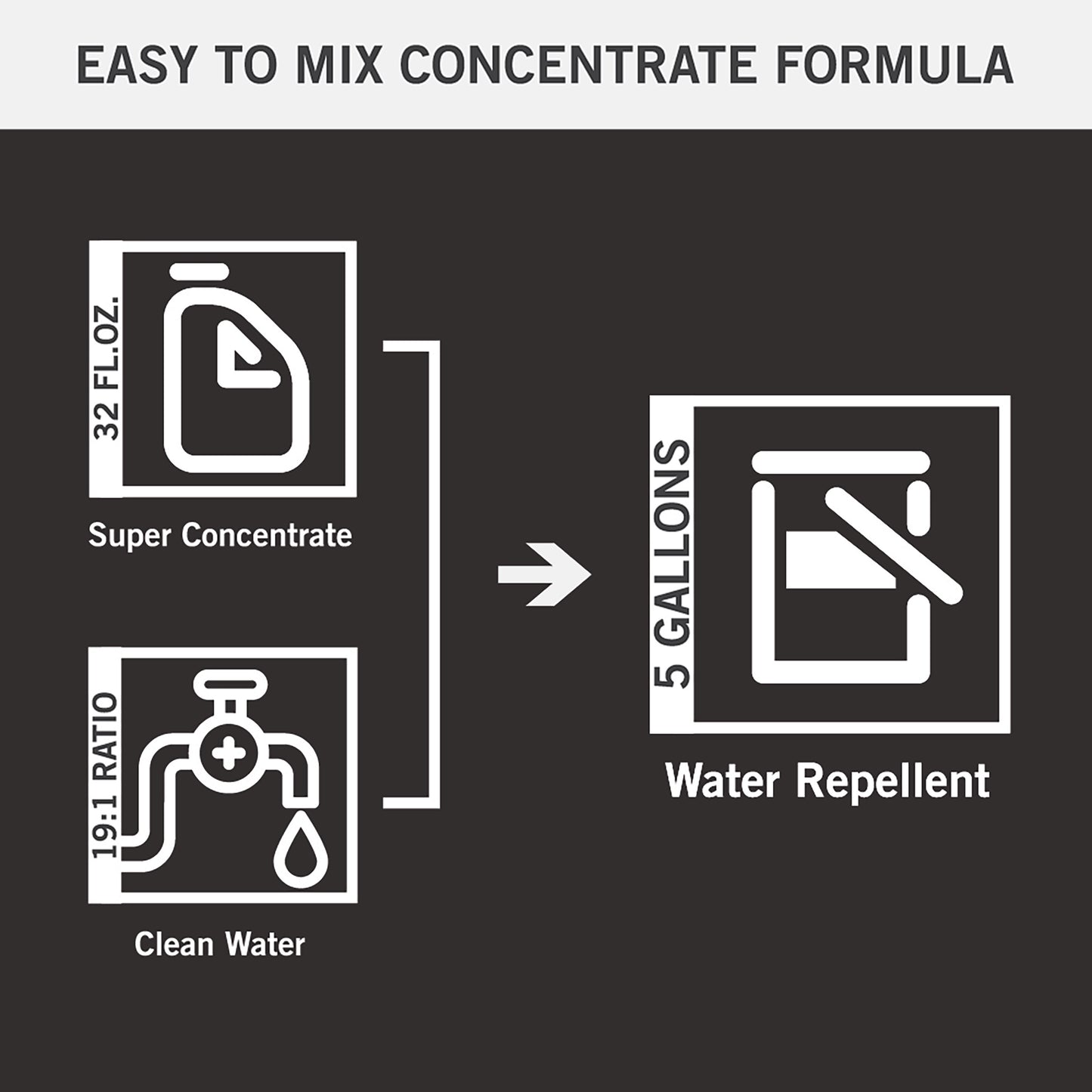

Why Choose A Concentrate?

Why Choose A Concentrate?

The Benefits of Using and Specifying Concentrates:

- Reduces carbon footprint

- Reduces job site and landfill waste

- Reduces worker and supply chain fatigue

Share

More Details

How To Apply

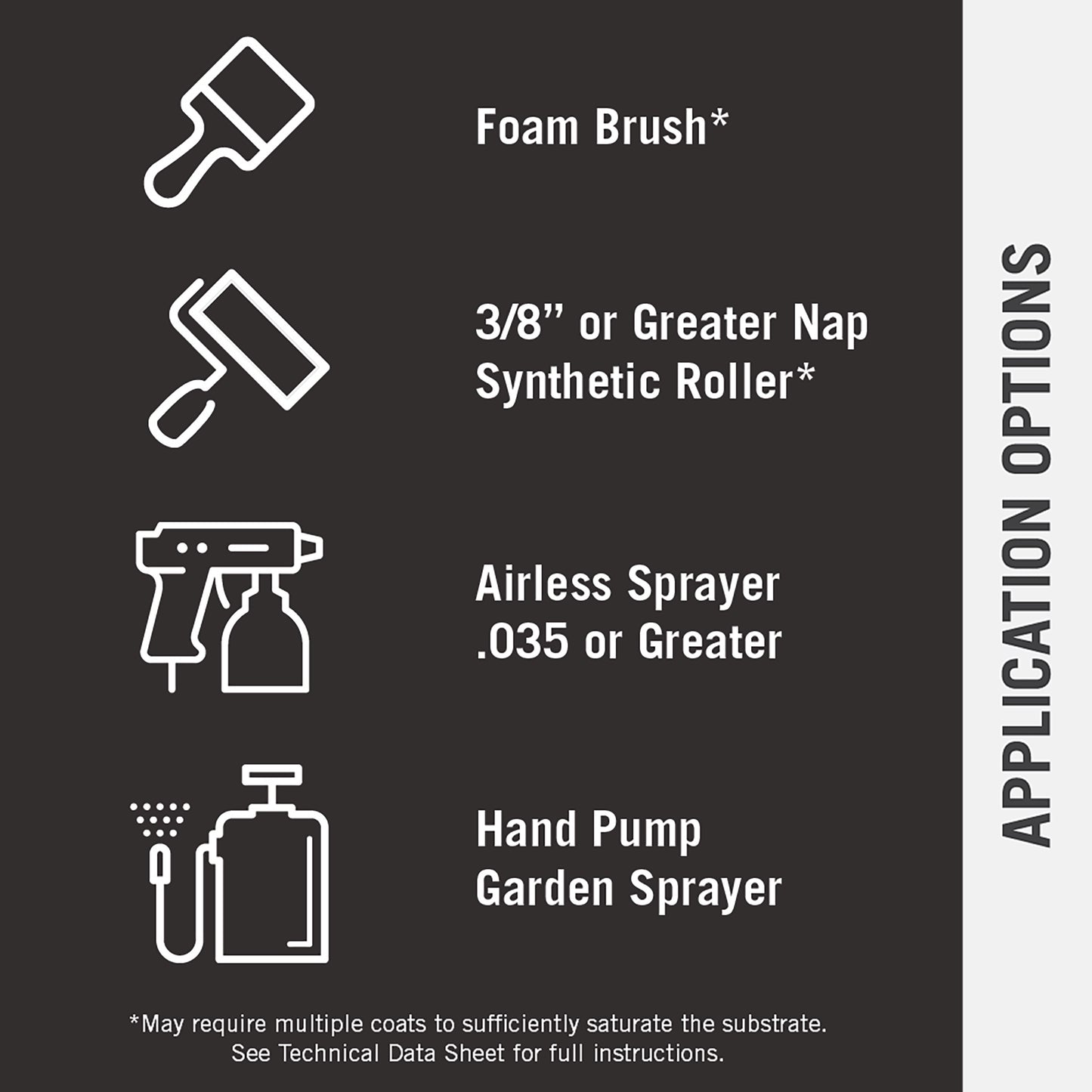

Spray on easily in a flood coat using an airless sprayer.

What is Micro-Lok®?

A proprietary ingredient that creates a micro-molecular chemical and mechanical bond between the water repellent chemicals and the substrate.

Superior Hybrid Acrylic Formula

High-performance modified silicone acrylic water repellent can be applied to concrete or stucco as a curing agent.

Primer And Water Repellent In One

Can be used as a primer to bind chalky surfaces. Protects wood and masonry surfaces from moisture damage.

Safe For The Applicator, End-User, and Environment

Contains <15 g/L V.O.C.’s, no carcinogens, very low odor and can be applied on interior and exterior surfaces.