RainguardPro

VandlGuard® Finish Coat

VandlGuard® Finish Coat

Couldn't load pickup availability

VandlGuard Finish Coat is a top coat for VandlGuard Five and VandlGuard Ten anti-graffiti systems. This water-based emulsion dries clear with a natural finish that will not yellow over time. VandlGuard Finish coat should not be used as a stand-alone product.

Details

Details

What It Is: A top-coat for VandlGuard Five and VandlGuard Ten non-sacrificial graffiti coatings

Surface Types: Concrete, Brick, Block, Wood (see TDS for full list)

Formulation: A Cross-linked Co-polymer

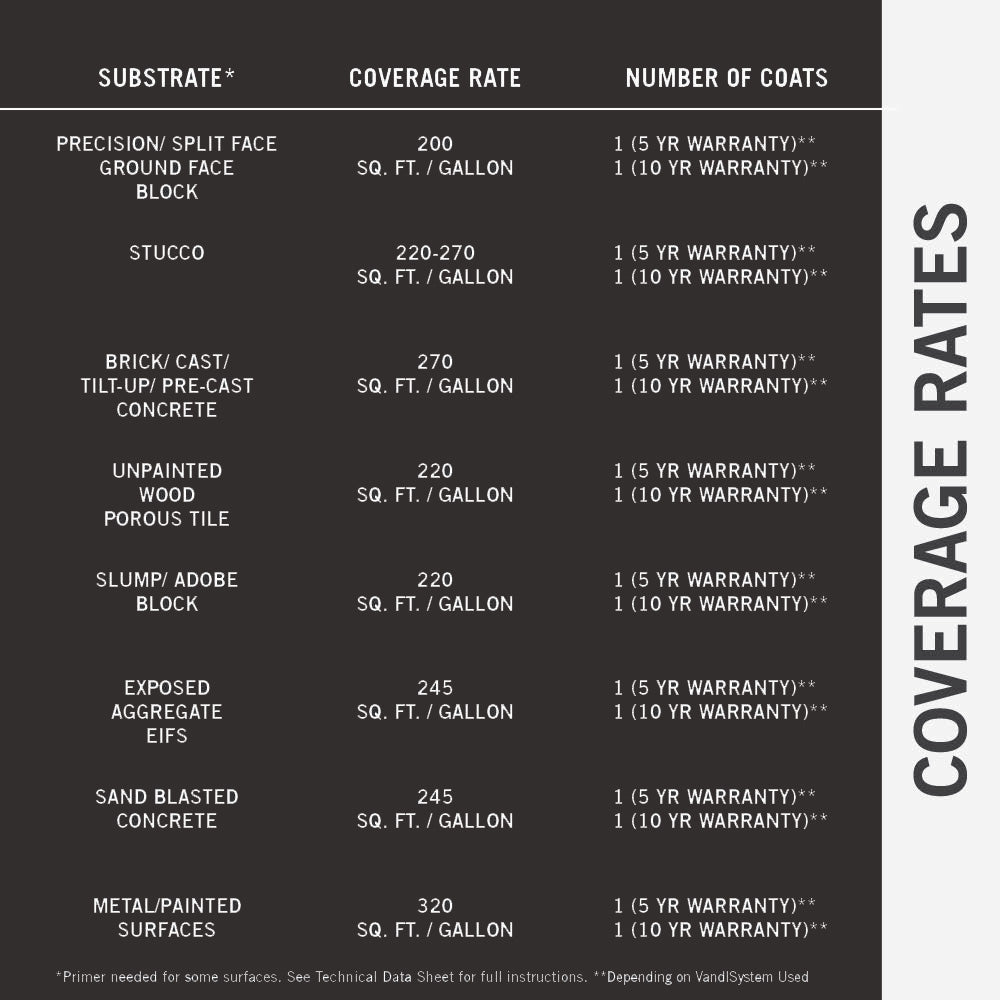

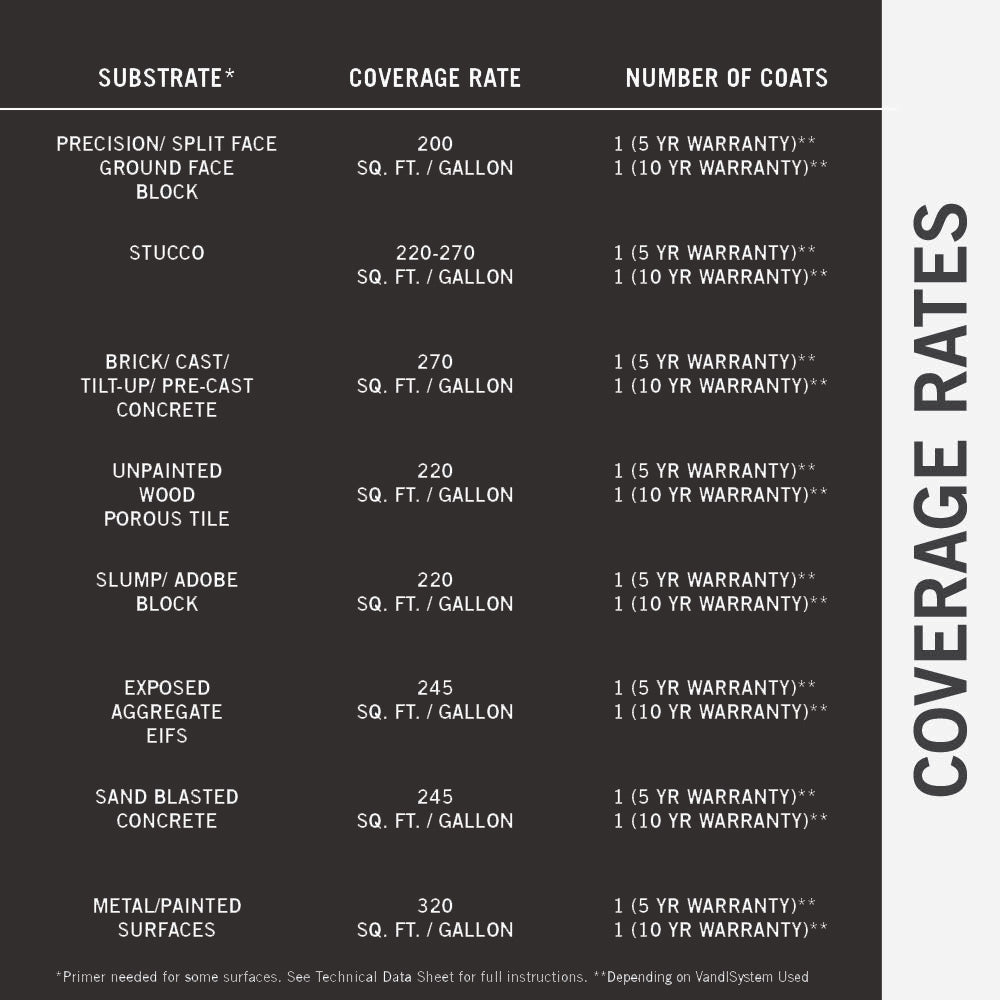

Coverage Rate: Approx. 220-320 sq. ft. / gallon (See TDS for details)

Share

More Details

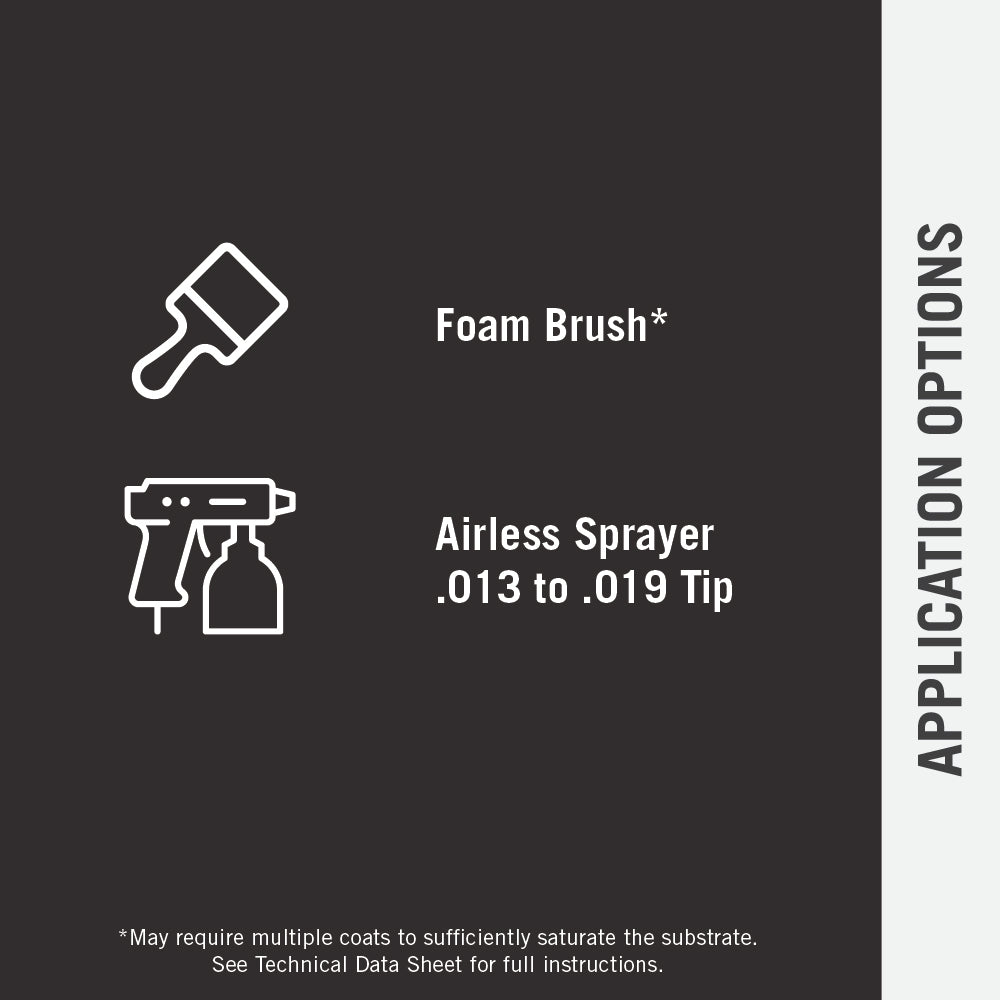

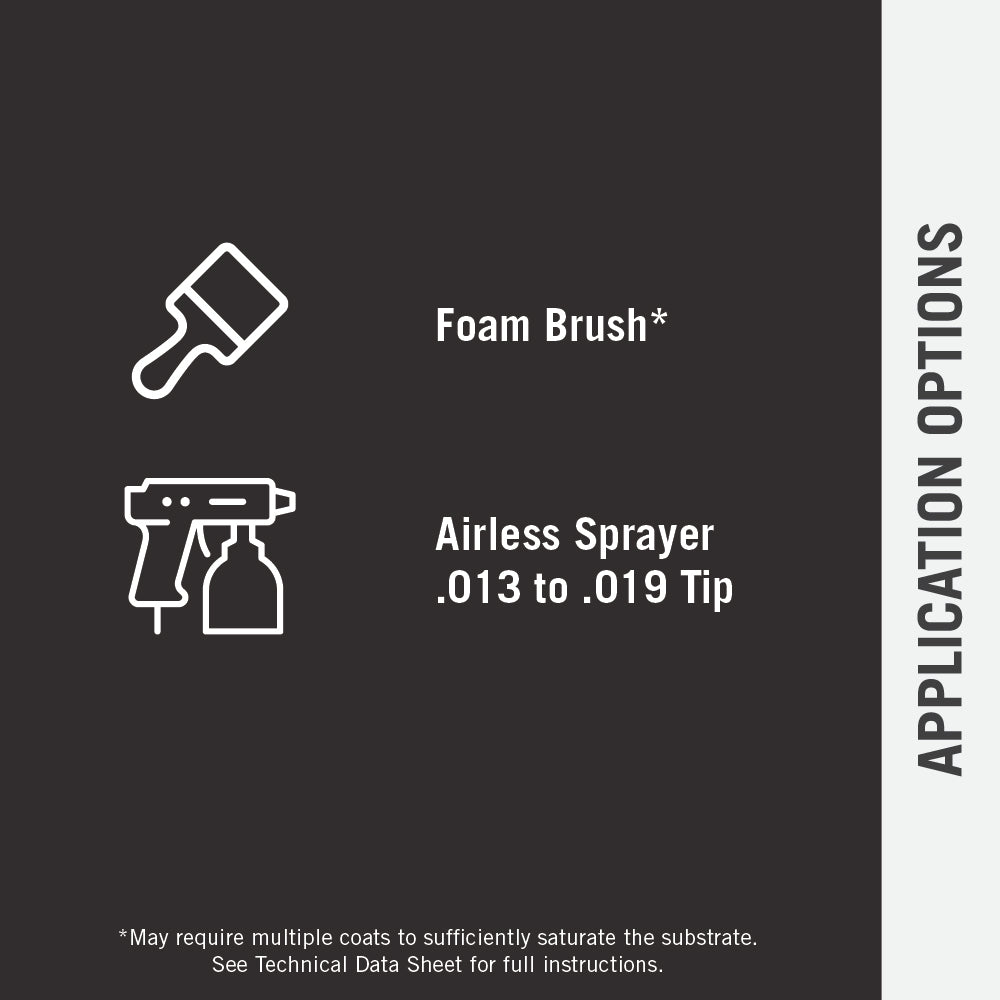

How To Apply

Spray on easily in a flood coat using an airless sprayer.

Top Coat for VandlGuard® Graffiti Systems

Protect your project from damage caused by spray paint, marker, and pen when used with VandlGuard Five or VandlGuard Ten.

Clear Finish

Preserve the look of the project with 100% breathable and virtually invisible protection that will not yellow over time.

Safe For The Applicator, End-User, and Environment

Contains less than 20 g/L V.O.C.’s, no carcinogens, very low odor, and can be applied on interior and exterior surfaces.