RainguardPro

VandlGuard® IsoFree® Aliphatic Urethane 2K

VandlGuard® IsoFree® Aliphatic Urethane 2K

Couldn't load pickup availability

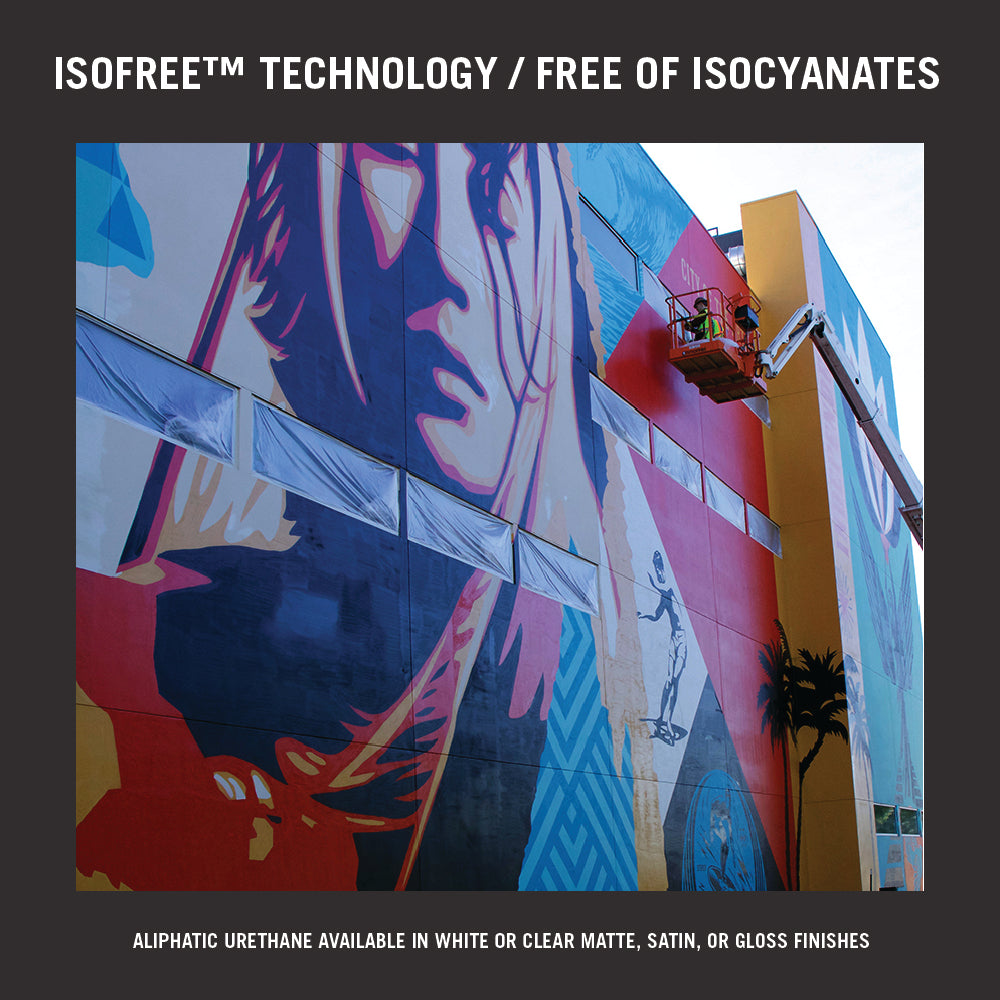

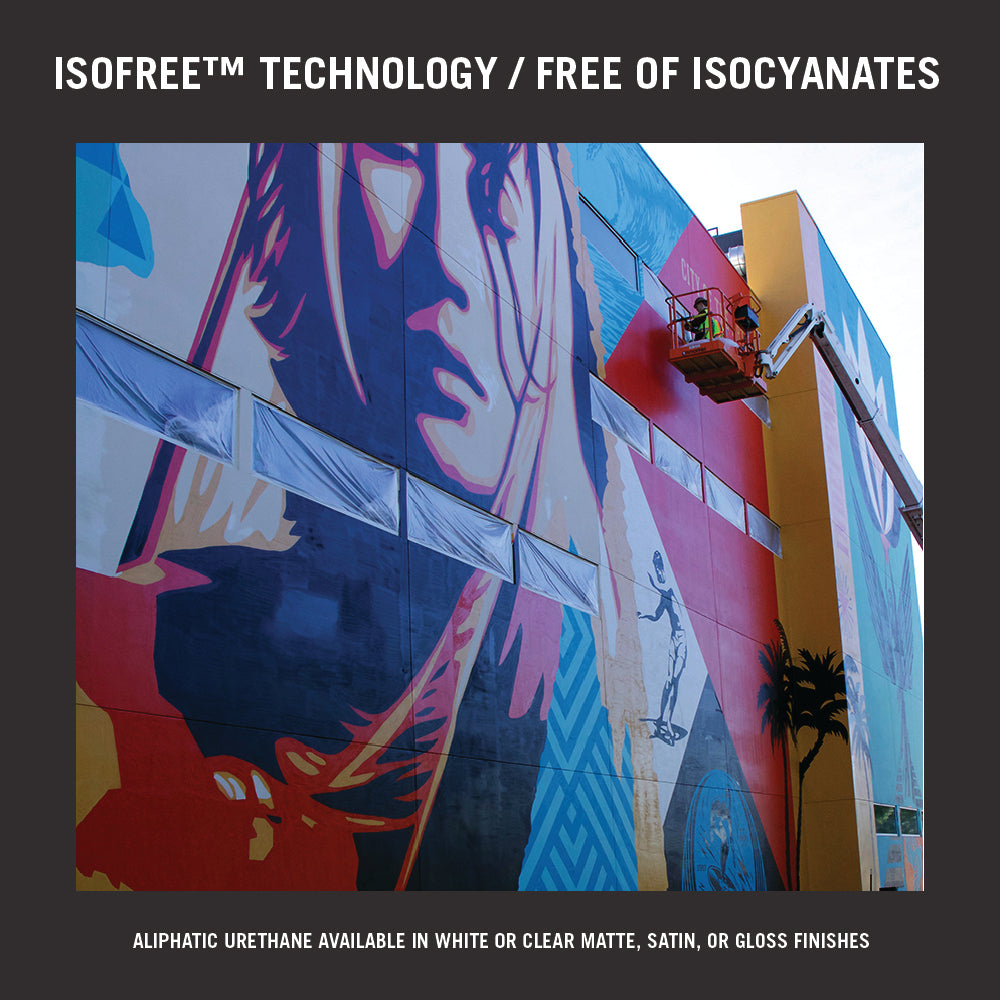

VandlGuard IsoFree is the first isocyanate free two-component, high performance, zero-VOC, odorless, water-based, aliphatic polyurethane paint/coating. VandlGuard IsoFree Aliphatic Urethane 2K provides years of excellent protection against harsh weather conditions, UV exposure, corrosion, and graffiti.

Details

Details

What It Is: An odorless non-yellowing, UV resistant, and non-sacrificial graffiti coating

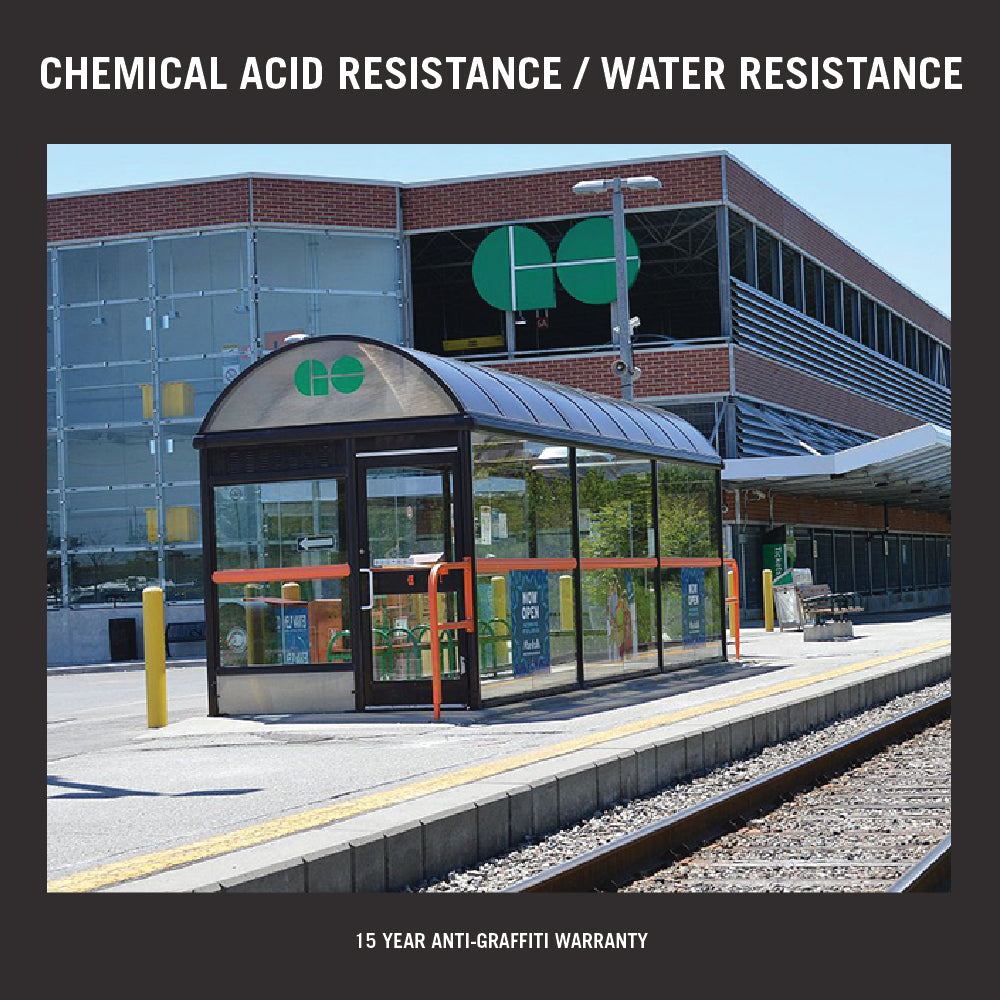

Surface Types: Concrete, Masonry, Metal, Wood (see TDS for full list)

Formulation: A Two-Part, Water-based Aliphatic Polyurethane

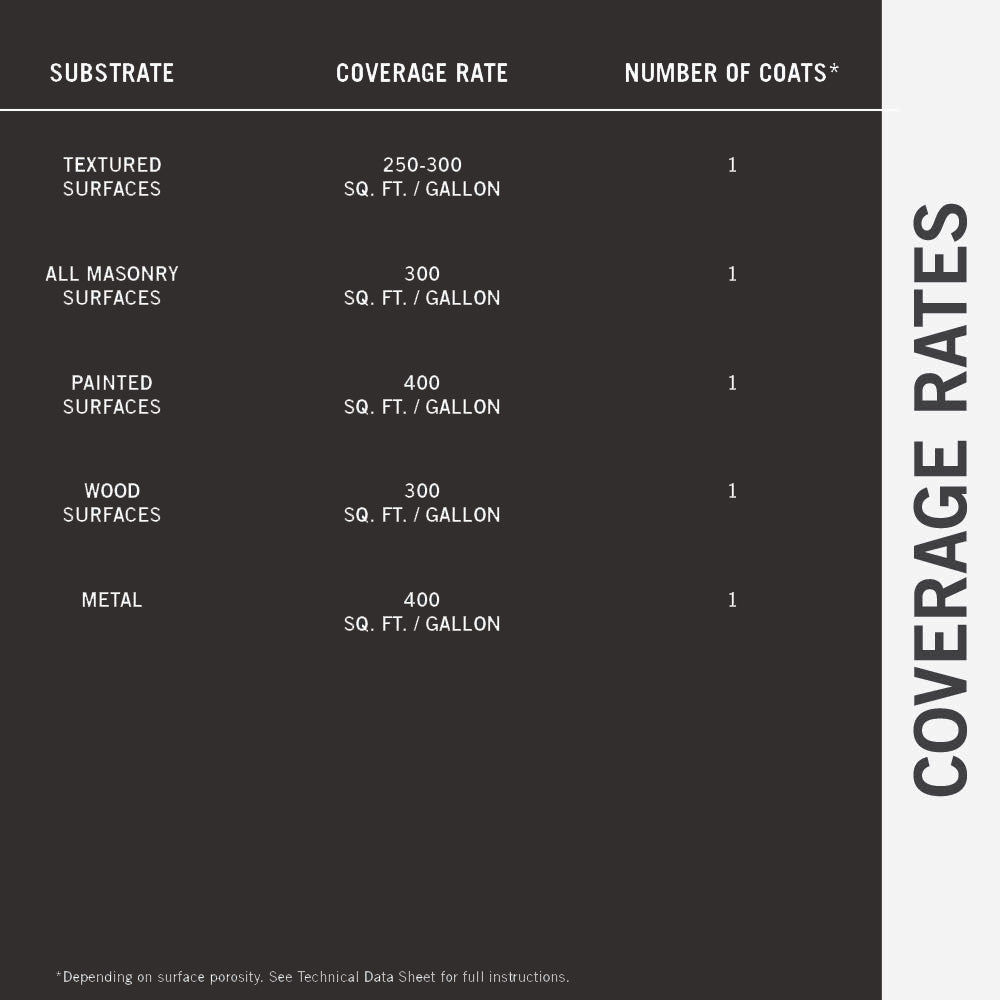

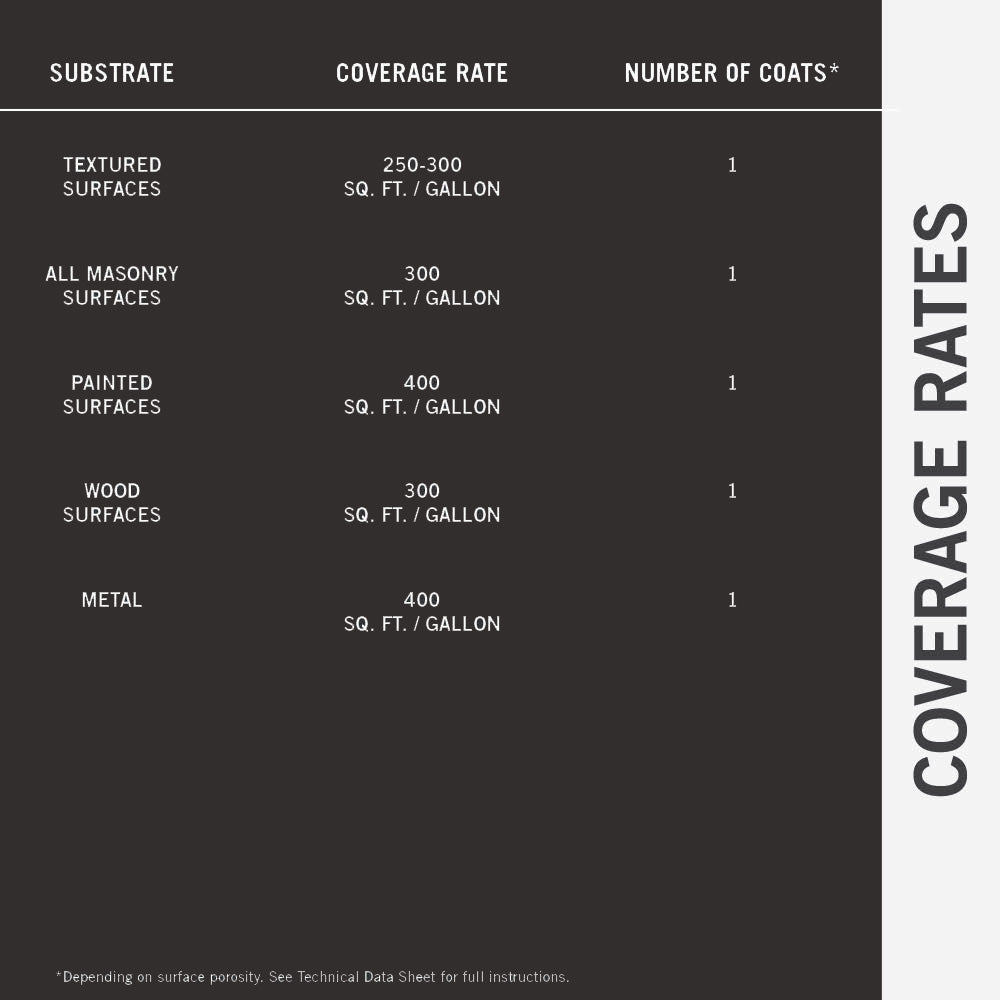

Coverage Rate: Approx. 250-400 sq. ft. / gallon (See TDS for details)

Tinting Instructions

Tinting Instructions

Clear should not be tinted.

White: Tint with up to 4 Oz of colorant / Gallon

Deep Base: Tint with up to 8 Oz of colorant / Gallon

What Comes In A Kit?

What Comes In A Kit?

- Part A 30 Fl. Oz. + Part B 2 Fl. Oz. = 32 Oz

- Part A 120 Fl. Oz. + Part B 8 Fl. Oz. = 1 Gallon

- Part A 480 Fl. Oz. + Part B 32 Fl. Oz. = 4 Gallons

See instructions (TDS) for dilution percentages

Share

More Details

How To Apply

Can be sprayed, brushed, or rolled on.

What Is IsoFree® Technology?

When Part B is mixed with Part A the crosslink reaction makes the combined product odor free, isocyanate free, and zero VOC’s. This creates a formula that is safe to apply for both the applicator and the environment.

Extremely Durable Protection

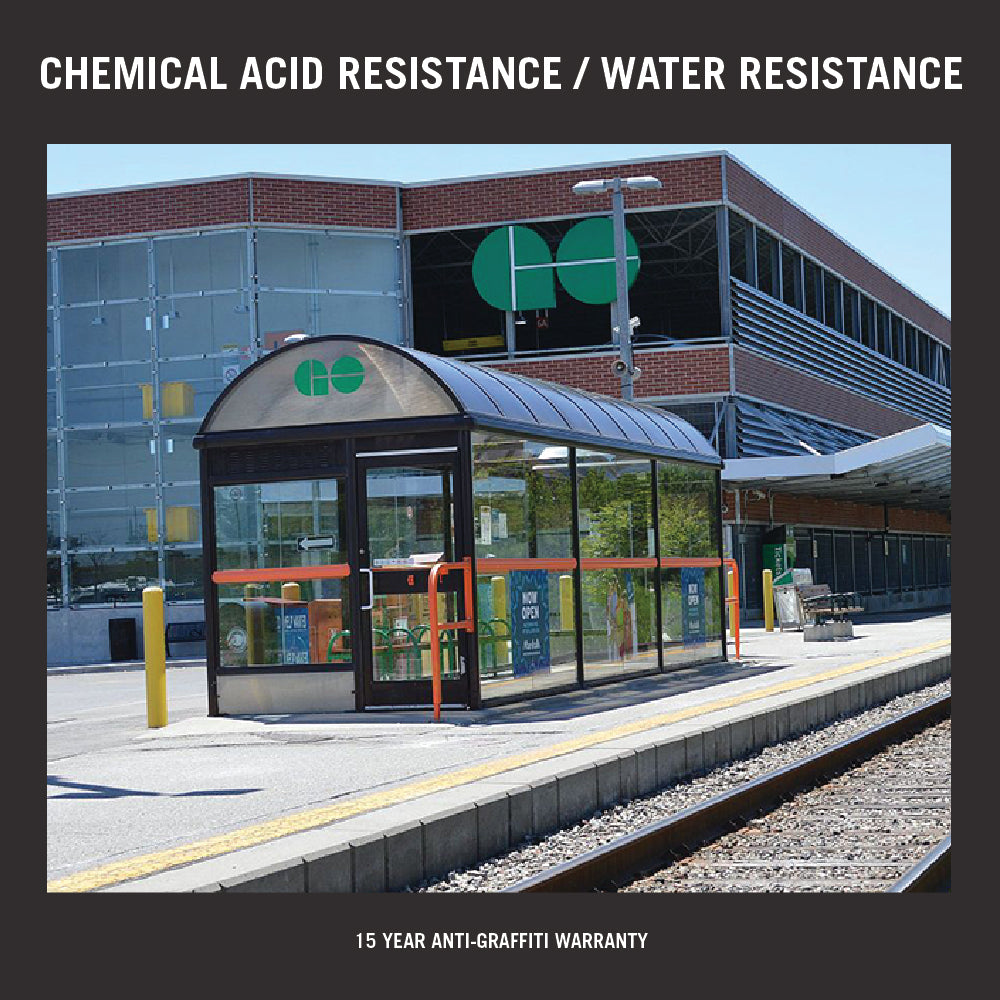

Outdoor weathering passes 10,000+ cycles and cleanability passes 160+ cycles

Protects Surfaces from Damage Caused by Graffiti

Protect your project from damage caused by spray paint, marker, pen, and some types of glue.

Safe For The Applicator, End-User, and Environment

Contains 0 g/L V.O.C.’s, no carcinogens, no odor, and can be applied on interior and exterior surfaces.