RainguardPro

VandlTop® Sacrificial Graffiti Coating

VandlTop® Sacrificial Graffiti Coating

Couldn't load pickup availability

VandlTop is a sacrificial graffiti coating works by “sacrificing” itself to ensure complete removal of any tagging. VandlTop allows for the removal of graffiti without the use of chemicals and will not yellow over time. VandlTop sacrificial graffiti coating protects the environment and sensitive building surfaces which could be damaged with traditional graffiti removal products. Removing graffiti from a surface also removes Vandltop, so you will need to reapply for further graffiti protection.

Details

Details

What It Is: A sacrificial graffiti coating

Surface Types: Concrete, Masonry, Stucco, Wood (see TDS for full list)

Formulation:A Water-based Blended Emulsion

Coverage Rate: Approx. 180-300 sq. ft. / gallon (See TDS for details)

Share

More Details

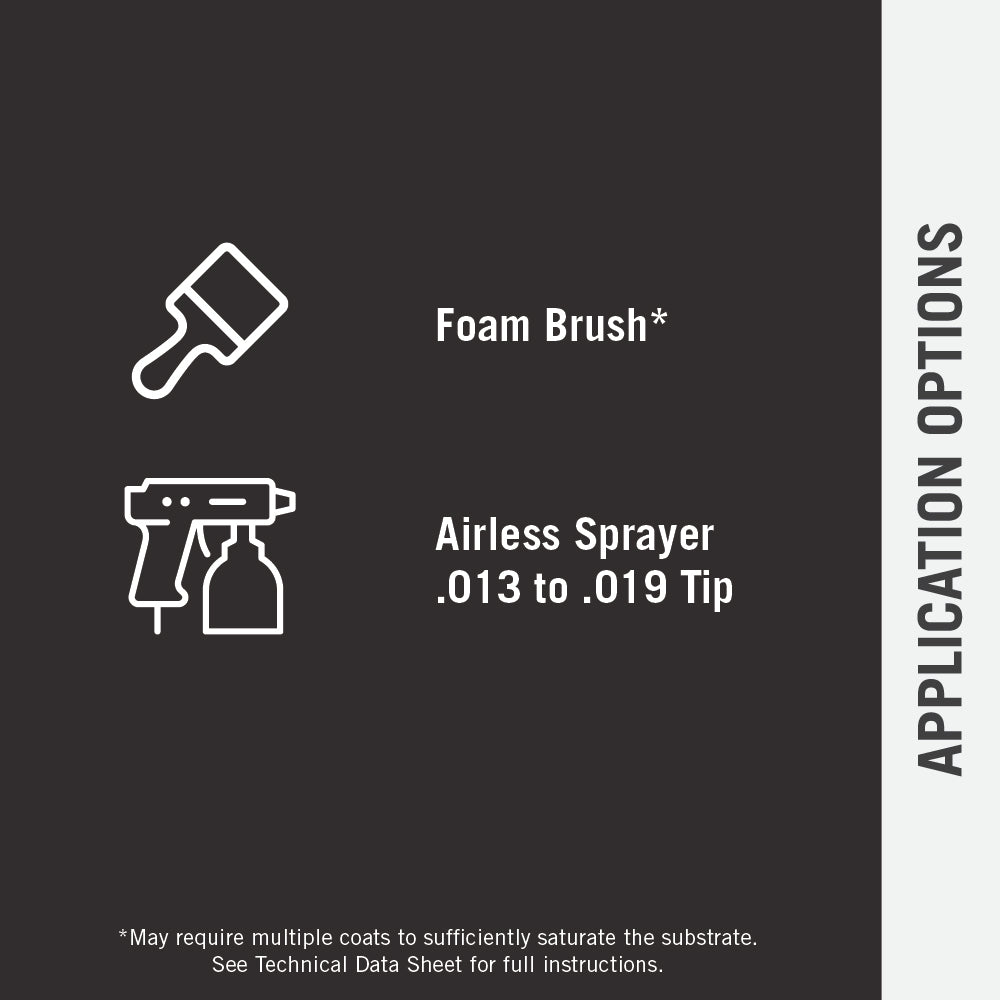

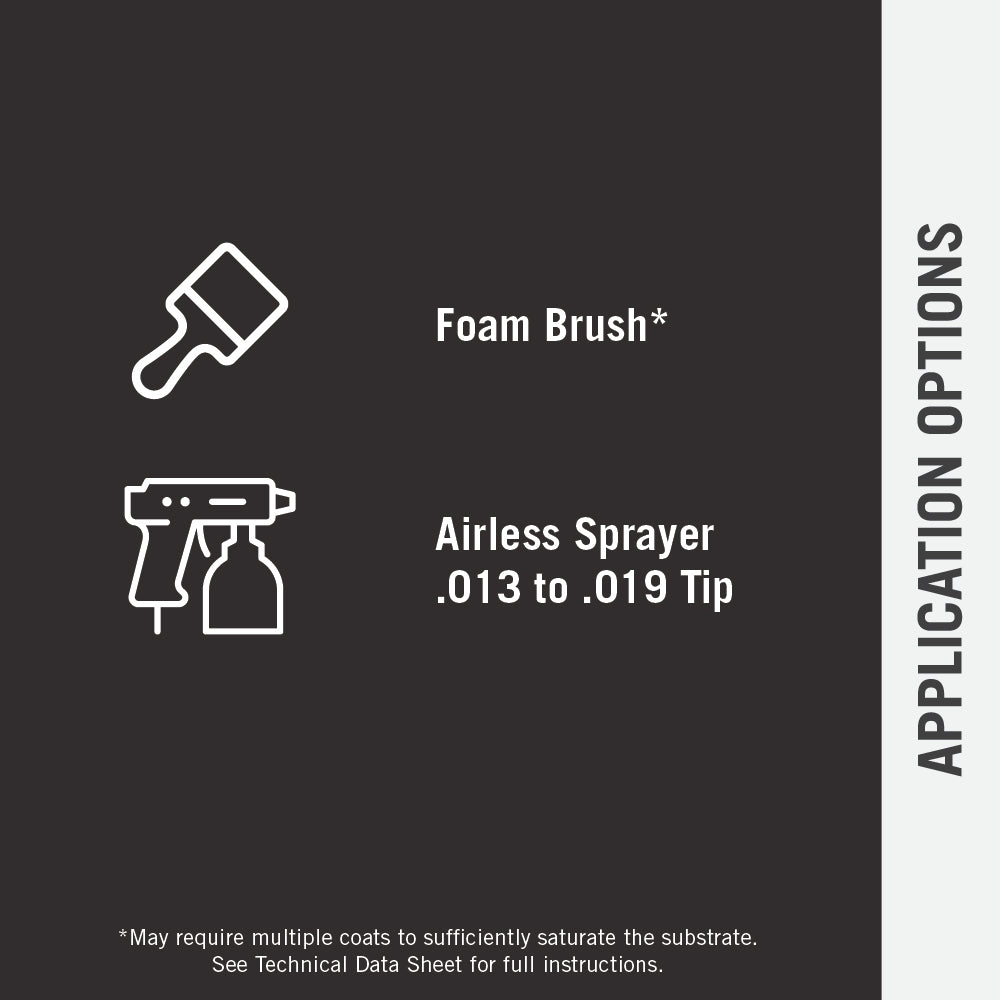

How To Apply

Spray on easily in a flood coat using an airless sprayer.

Natural Finish

Clear, matte, and non-yellowing formula with minimal change in the look of a building.

Sacrificial Anti-Graffiti Coating

Allows for the removal of graffiti without the use of chemicals. Protects sensitive building surfaces.

Safe For The Applicator, End-User, and Environment

Contains less than 20 g/L V.O.C.’s, no carcinogens, very low odor and can be applied on interior and exterior surfaces.